UAS Lidar Technology Helps Complete Mine Ground Inspections Quickly and Safely

On 17 May 2020, the LKAB Kiruna Mine experienced a seismic event that resulted in a significant fall of ground, deep within the site. The mine was immediately closed and mine managers began determining how best to assess the damage. Emesent partner, AMKVO, a Swedish remote sensing specialist, was contracted to conduct damage inspections at Kiruna Mine, commencing 31 May 2020. AMKVO spent four days underground mapping the damage in the mine, using Hovermap mounted to a DJI M210 drone or handheld, at a depth of 1236 meters below the surface.

Emesent Hovermap technology helps LKAB complete fall of ground inspections quickly and safely at Kiruna mine. Swedish mining company LKAB mines and processes iron ore for the global steel market. Its mine in the northern city of Kiruna commenced production in 1898. Today, it’s the world’s largest underground iron ore mine, producing around 27 million tonnes of iron ore a year.

The Challenge: Safely Surveying the Damage After a Seismic Event

On 17 May 2020, the LKAB Kiruna Mine experienced a seismic event that resulted in a significant fall of ground, deep within the site. The mine was immediately closed and mine managers began determining how best to assess the damage. Historically, mining companies were forced to carry out this exercise manually, making notes and sketches and taking photographs where possible. As well as being dangerous, manual inspections are labour-intensive, time-consuming and inaccurate. LKAB management sought a means of carrying out a comprehensive, accurate survey of the damage, without risking the safety of LKAB employees or contractors.

"I was impressed by how well Hovermap worked." - Alexander Paulusson, CEO | AMKVO AB Data

The Solution: Send in Hovermap

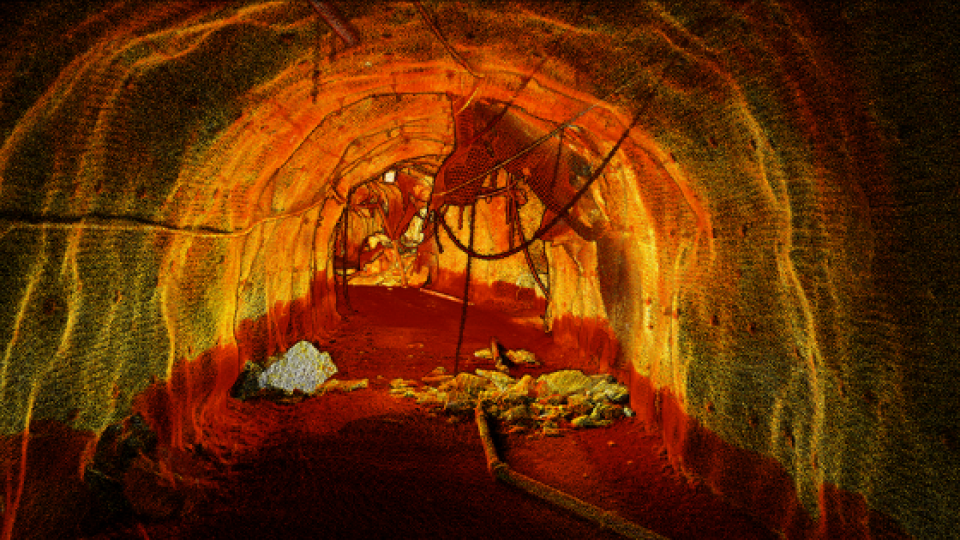

Emesent partner, AMKVO, a Swedish remote sensing specialist, was contracted to conduct damage inspections at Kiruna Mine, commencing 31 May 2020. AMKVO spent four days underground mapping the damage in the mine, using Hovermap mounted to a DJI M210 drone or handheld, at a depth of 1236 meters below the surface. AMKVO completed 30 scans in challenging conditions, navigating the drone around collapsed services, ventilation bags, and rockfalls. To fly through narrow openings, AMKVO adjusted Hovermap’s virtual shield (collision avoidance) settings. The dust had little impact on Hovermap’s simultaneous localization and mapping (SLAM) collision avoidance and point cloud capture quality.

“The dust didn’t affect the flying or the scans. In dusty areas, the scans had noise around the drone, but that was easy to filter out. Even in the absolute worst conditions, where we couldn’t see the drone, we still got a perfect tunnel scan. I was impressed by how well Hovermap worked.” Alexander Paulusson, CEO | AMKVO AB Data was sent to the surface as it was collected for analysis by LKAB’s mine planning and safety teams.

Deliverables

Before leaving the site, AMKVO delivered georeferenced point cloud data sets of tens of kilometres of mapped drifts, still images and animated films. AMKVO conducted over 30 flight and walking scans, at a depth of 1,236 meters below the surface, to map the damage throughout kilometres of drifts in Kiruna.

Using Accurate Data to Plan the Path Forward

Using Hovermap to scan the Kiruna Mine enabled LKAB to obtain an accurate picture of the damage within weeks of the seismic event occurring, without risk to human safety. The data was used to inform remediation planning, including the extent of rock reinforcement required and the repairs necessary to damaged plant and equipment within the mine. A significant seismic event typically generates considerable media and community interest. Having a comprehensive understanding of the damage allowed LKAB to provide stakeholders with timely status updates and their proposed remediation schedule. The videos created by AMKVO allowed LKAB workers and those living in the Kiruna area to view the damage firsthand and develop an appreciation of the work necessary for operations at the mine to recommence. LKAB subsequently purchased three Hovermap scanners for ongoing use in mine sites across Sweden.

Do you have questions about this case study?

Get in touch with Emesent, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

Related products

![Do-Giant-Tortoises-Make-Good-Neighbors-1[1].jpg](https://cdn.geo-matching.com/vRMO2Edp.jpg?w=320&s=a6108b2726133ff723670b57bc54c812)