Sodex Constructs Solution to Building Industry’s Excavation Problem With Help of Imu and GNSS Sensors

How do you measure the volume of a hole in the ground? If the hole is small and rectangular, it is simple. But what about the giant hole dug for the foundations of a city centre skyscraper or a new underground train station? It will generally be irregular in all three dimensions and very large. Accurately measuring the volume of excavation works is a little-known but surprisingly contentious, time-consuming and expensive process for building companies. The work calls for the services of highly paid and scarce surveyors. Now Sodex Innovations, a technology start-up company based in Austria, has developed a product which automates cavity measurement, eliminating the need for site visits by surveyors. This technology is quicker, more convenient, and provides more useful data than conventional surveys – and it depends on Movella’s Xsens MTi technology.

Excavation: a money pit

Holes are big businesses in the construction industry. Building companies pay contractors for excavation work: the bigger the hole, the higher the excavation fee. The material dug out of the ground – the ‘spoil’ – also has a monetary value. This might be the cost to dispose of it. Or, if the spoil is a material such as gravel which can be repurposed, it has value to a customer who can buy and use it. Again, the bigger the volume of spoil, the higher the value.

So measuring holes and spoil is a crucial function of any large building project. Classifying the type of material in the soil is also essential to determine whether it has any resale value or requires special disposal measures.

Today, surveying is the preserve of highly qualified professionals. Because of their scarcity and high levels of training and education, these professionals command high fees for their work. And since they are required to travel from site to site to perform surveys, building companies frequently have to organise their operations around the availability of a surveyor rather than fitting surveys into building schedules.

And, of course, any function performed by a human is subject to the risk of human error. This means that disputes over surveys are surprisingly common, adding yet more friction to the seemingly simple business of digging a hole in the ground.

Ralf Pfefferkorn encountered this problem when developing a prototype for a robot excavator as a student project. Excavation appeared to be ripe with the potential for automation. So on graduation in 2017, Ralf and two colleagues, Raphael Ott and Bernhard Gantner, founded Sodex Innovations. Some five years later, Sodex gained the first customers for its fully automatic device for volumetric measurement of cavities, the SDX-4DVision system.

The surveying machine: laser and camera-based technology

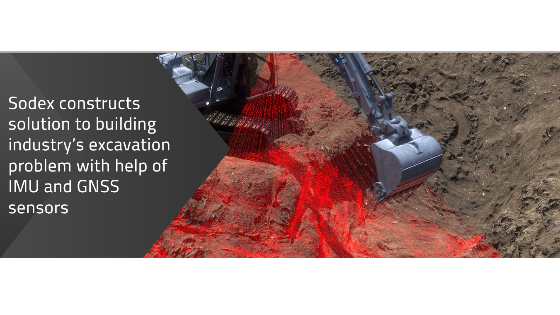

The SDX-4DVision product is a system which combines high-technology laser scanners and cameras to calculate the 3D dimensions of an excavation. The accumulation of millions of measurements enables the system to build a detailed point cloud from which very accurate volumetric measurements can be calculated in real-time (see Figure 1). As well as a laser scanner, the SDX-4DVision has a video camera which adds photographic documentation to the survey.

Fig. 1: the laser scanner creates a continually updated scan of the depth and extent of a hole

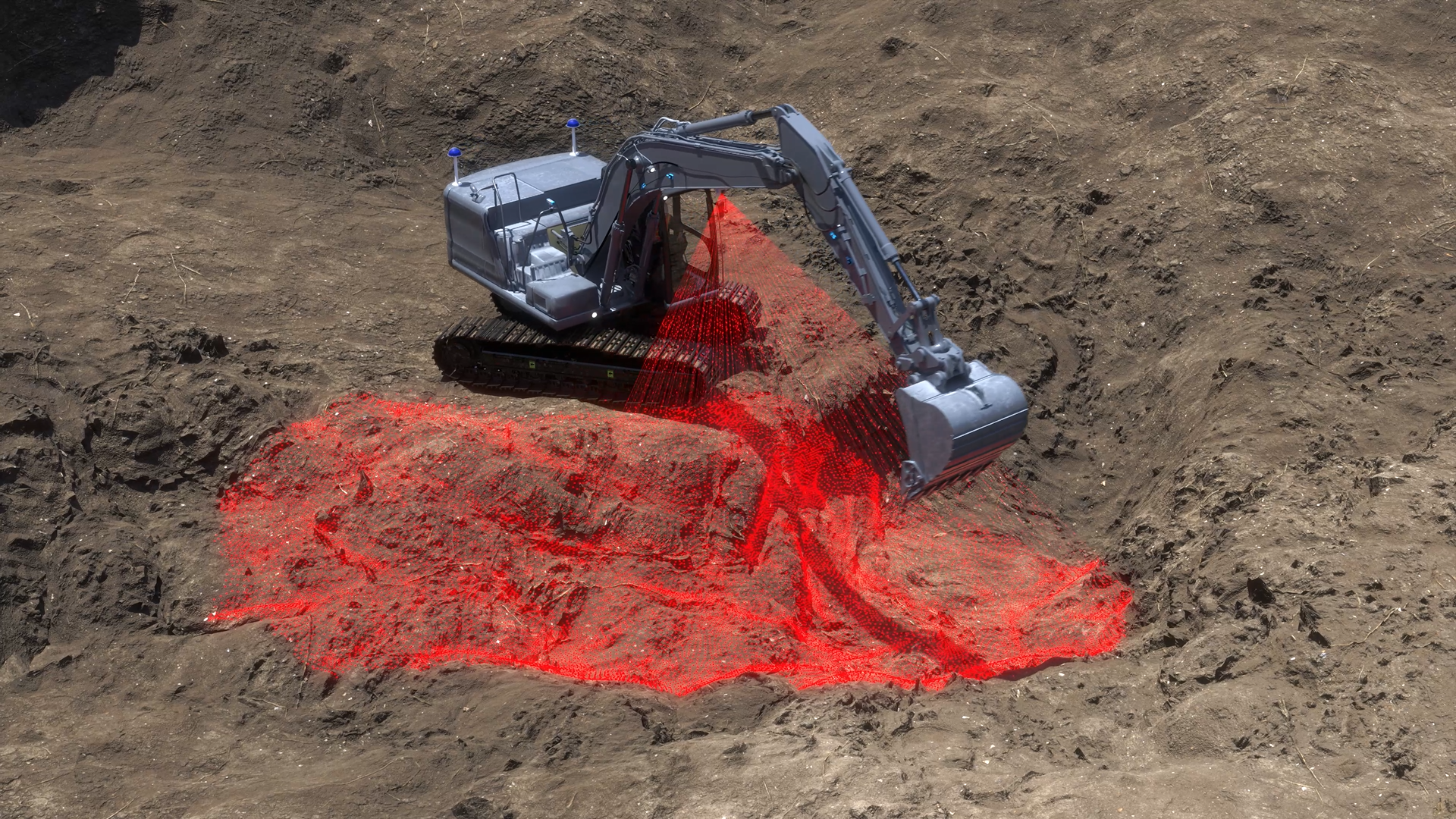

The SDX-4DVision unit is mounted on the boom of an excavator, from where it has an uninterrupted view of the ground (see Figure 2). The boom is the arm which controls the scoop and constantly moves in all three dimensions

Fig. 2: the SDX-4DVision scanner is compatible with any type of excavator

To use the point cloud as the basis for measuring the size of a hole, the system requires continuously georeferenced position data. It also needs to constantly adjust its calculation of the laser measurements to take into account of the tilt and 3D position of the boom-mounted SDX-4DVision unit relative to its resting position.

These sets of real-time motion data are provided by Movella motion sensors. The Xsens MTi-630R AHRS (attitude and heading reference system) provides the acceleration, rate-of-turn and heading information so that the position of the boom relative to the chassis of the excavator can be continuously tracked.

A second sensor, the Xsens MTi-680G RTK GNSS/INS, provides precise geolocation data from a satellite positioning signal supported by RTK (Real-Time Kinematics) signal enhancement, giving total geolocation accuracy of ±3cm.

This sophisticated hardware platform supports the operation of Sodex’s advanced software for calculating the volume of a cavity in real time and for displaying this information in an easy-to-use format, in real-time, at the Sodex cloud computing portal.

Transforming construction business processes

Ralf Pfefferkorn says that the construction industry is just beginning to learn all the benefits it can derive from implementing automated volume measurements with the SDX-4DVision. The most obvious advantage of using the SDX-4DVision is that surveying no longer requires a surveyor, with all the advantages of cost and convenience that this brings. Crucially, the Sodex technology also eliminates the risk of conflict, which often arises after conventional surveys. Ralf Pfefferkorn says. ‘Big property companies are starting to mandate the use of the SDX-4DVision, because it provides a single, validated source of measurements and gives a trusted basis for billing and invoicing which all parties in a construction project can agree to be bound by.’

But he says that even more value can come from the opportunity to rethink business processes. He says, ‘With a surveyor, the construction project manager gets a single snapshot. The difference with the SDX-4DVision is that measurements are produced continuously in real-time, so project managers always know the exact status of an excavation minute-by-minute: how close it is to completion, whether some parts of the site take longer to excavate than others, and so on. So the SDX-4DVision product gives builders a completely new tool for better project management and the better design of workflows and construction processes.’

Of course, none of this would be possible if the SDX-4DVision product’s measurements were not highly accurate, and for this, he says, Sodex has the Xsens MTi-630R and Xsens MTi-680G sensors to thank. ‘The selection of the right motion sensors was a crucial part of the system design. Fortunately, we found the MTi-600 series, which gives us the right combination of high accuracy and a high output data rate at an affordable price for our customers and us. We are delighted with the performance of the devices in the SDX-4DVision.’

And there is every sign that the construction industry is delighted with the innovation of automated volumetric measurement, a sure sign that Sodex has a successful and exciting future ahead of it.

Do you have questions about this case study?

Get in touch with Movella, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

![Do-Giant-Tortoises-Make-Good-Neighbors-1[1].jpg](https://cdn.geo-matching.com/vRMO2Edp.jpg?w=320&s=a6108b2726133ff723670b57bc54c812)