Mobile Imaging Application for Assessing Pavement Condition

The purpose of this application of mobile imaging technology is to perform a Network Pavement Condition Assessment for the entire roadway network maintained by Cities and Counties. To do this, the current pavement characteristics and the condition of the pavement will be evaluated using the American Public Works Association (APWA) American National Standards Institute (ANSI) standardized evaluation methodology.

The approach is to utilize vehicle-based mobile imaging services to rapidly acquire, assess and map roadway pavement condition characteristics. The use of this two cameras mobile imaging system allows Southeastern Surveying and Mapping Corporation (SSMC) to take advantage of specialized data collection equipment to automate much of the pavement condition assessment. This results in a superior deliverable to the City at a much lower cost than if SSMC was to perform the project using conventional "feet on the ground" assessment techniques.

Image Capture Technology

In the past, manual surveys have been used by most agencies to collect pavement distress data. Manual surveys are labour and time-intensive, and data reliability depends on training and inspector performance. A number of studies have shown that manual ratings have high levels of variability with respect to inspector repeatability as well as high inspector-to-inspector variability. Image-based data collection systems produce permanent pavement surface images, offering the advantage of correlating inspector analysis results for accuracy and repeatability. An additional advantage to using fixed images is the ability to re-calibrate inspectors who tend to drift from desired interpretations with time. Fixed images also provide a consistent calibration for new inspectors. The combination of establishing inspector performance requirements and performing Quality Control (QC) monitoring enables the production of high-quality consistent data. Image-based data collection also provides a record of non-pavement assets such as traffic signs. These images can be made available to other areas of the City to aid in planning and maintenance.

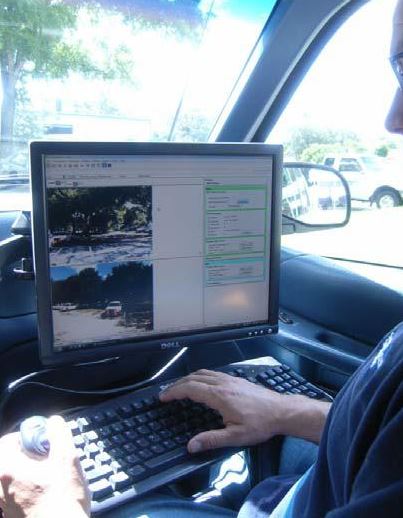

Mobile Imaging Vehicle Acquisition

To collect the imagery for the Pavement and Right of Way Asset Data Collection, the SSMC team worked with the staff of NorPix to develop a Mobile Imaging Vehicle equipped with two high-speed imaging cameras logging data at up to 10 images per second to an on-board computer linked to a submeter GPS receiver. This system allows the field team to drive at posted speeds and collect images from each camera at intervals of 5 to 10 feet.

The cameras are mounted on the vehicle in differing orientations with both wide-angle and telephoto lenses to obtain the maximum field of view and image coverage. The camera subsystem of the Mobile Imaging Vehicle consists of 1.3-megapixel Prosilica GC1350C Color cameras capturing images at a resolution of 1360 x 1024.

The cameras are connected to the host computer with a Gigabit Ethernet interface which is far superior to the more common Firewire interfaces. This allows the SSMC team to capture images at more frequent intervals and faster drive speeds without dropping or losing images. All of the cameras are controlled using the StreamPix software.

NorPix configured a system for Southeastern Surveying to accommodate multiple camera configurations with up to 5 cameras. A Trigger box is utilized to fire all cameras simultaneously. Each image collected by the cameras is tied to a GPS position using the StreamPix GPS Positioning Module to show where the camera was located when the image was captured.

The modular design of the mobile imaging platform allows the SSMC team to swap lens configurations and camera orientations alternating between wide-angle and telephoto views to tailor the imaging vehicle to the data collection needs of our clients.

The Mobile Imaging Vehicle is staffed with a two-man crew consisting of a driver, and a navigator/camera operator monitoring the collection of the images. The driver focuses on operating the vehicle, watching surrounding traffic and receiving navigation instructions from the camera operator.

The camera operator uses the StreamPix software to monitor and adjust the quality of the images collected from all of the cameras simultaneously and navigates the vehicle to make sure that all roadways are imaged in both directions.

Collecting 5 to 10 images per second from the moving vehicle allows the team to rapidly capture pavement images at posted speed limits. After downloading the images, each image is tied to a GPS position on the map showing where the vehicle was located when the image was taken and the orientation of the camera.

This allows a Pavement Distress Technician in the office to review the sequence of images, moving forward and backward with multiple camera angles to identify distresses, assess the condition of the pavement, and identify and locate the traffic signs.

This approach will significantly reduce both the time and cost of fieldwork in comparison to more manual techniques.

By orienting cameras at various angles, large quantities of pavement and right of way data can be captured safely as the vehicle travels the roads at normal posted speeds.

Since the cameras and StreamPix software collects sequential images at rates up to 10 frames per second or more, these images can be viewed in the office using software through which a user can perform a "virtual drive" down a road. The speed at which this drive is conducted is controlled by the user. The identified pavement distresses are captured using a "point and click" approach. This approach has many advantages over other methods including:

- Higher Quality: The virtual drive can be stopped, reversed, and slowly reviewed as many times as necessary to analyse the pavement distresses from multiple camera angles.

- Faster Condition Assessment: Because the images are collected by a vehicle moving at normal speeds, the time required to capture the data in the field is dramatically reduced.

For Pavement Analysis, high-resolution digital cameras are precisely located and mounted above the roof of the Mobile Imaging Vehicle. One camera is looking forward for an overall right of way view and a second camera at the rear of the vehicle is pointed down at the pavement to capture a wide-angle pavement view.

Geographic positioning data received from GPS satellites is tied to the image sequences and is also stored on the server's disks in real-time. Multiple camera views from all cameras are displayed on a screen inside the vehicle. Images are constantly monitored by Imaging Technicians as the images are captured to ensure that the captured images have the proper exposure, brightness and contrast.

The Mobile Imaging Vehicle collects up to 180,000 images per day as the vehicle is driven. Collecting 5 to 10 images per second from the moving vehicle allows the team to rapidly capture clear images of the pavement and right of way at posted speed limits.

Using custom software developed by SSMC's in-house Programmer / Analyst, each of the thousands of collected images is linked to a GIS point file representing the location and orientation of the camera when the image was captured. This allows a Technician using GIS software in the office to select an image anywhere along the roadway, review the sequence of images, moving forward and backwards to identify pavement distresses within the roadway.

Image Georeferencing

After Images are collected, each image is tied to a position on the map. SSMC has designed the data collected by the mobile imaging system to be processed as standard data within a Geographic Information System (GIS). This allows a Pavement Distress Technician to use standard GIS tools to select an image from the map, view the images to identify pavement distresses.

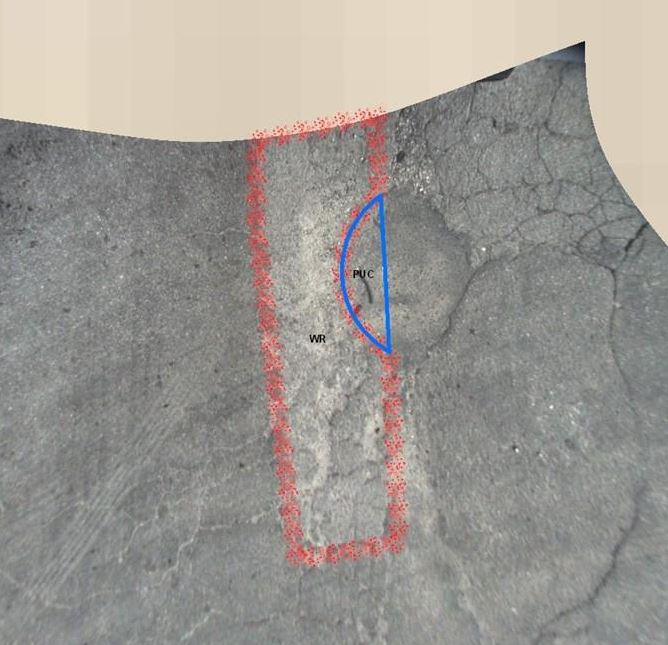

Once pavement distress has been identified, the distress needs to be quantified for entry in the PAVER software. For example, in the longitudinal and transverse cracking visible in the images above, the lengths of the cracking needs to be measured and associated with the appropriate Roadway Section in the PAVER database.

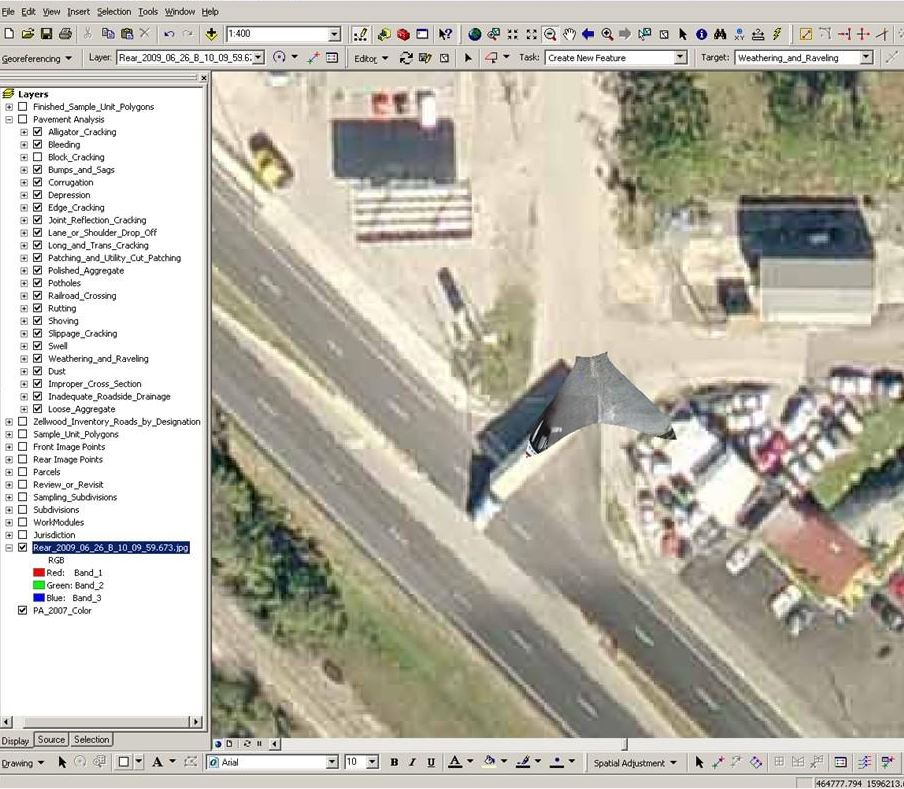

GIS as a Tool for Pavement Distress Analysis

With the advent of Geographic Information Systems (GIS), a new set of tools have been developed to manage the spatial component of the pavement distresses. The GIS data can store the type, severity and quantity of the distress along the roadway, and these distress in the GIS database become a physical record documenting both the quantity and the location of the distresses. When the roadway is re-inspected a few years later the Pavement Distress Technician reviews the roadway photos, compares the visible distresses in the GIS to the distresses in the photos and then verifies or updates the severity of the existing distresses that have not been repaired, removes previous distresses that have been repaired, or adds new distresses that have been identified. This eliminates the continuous re-measurement of the same pavement distresses at each update and significantly reduces the cost to re-inspect the roadway network in subsequent years.

The key to this process is the ability to easily correlate the roadway image taken from the vehicle to the position on the ground shown on the map. Typical mobile mapping platforms require users to select a common point in two or more images to triangulate and establish a coordinate position on the ground. This is a time-consuming process. To map the location of a rectangular pavement patch with 4 corners, the Technician must identify all four points in two different images to calculate coordinates.

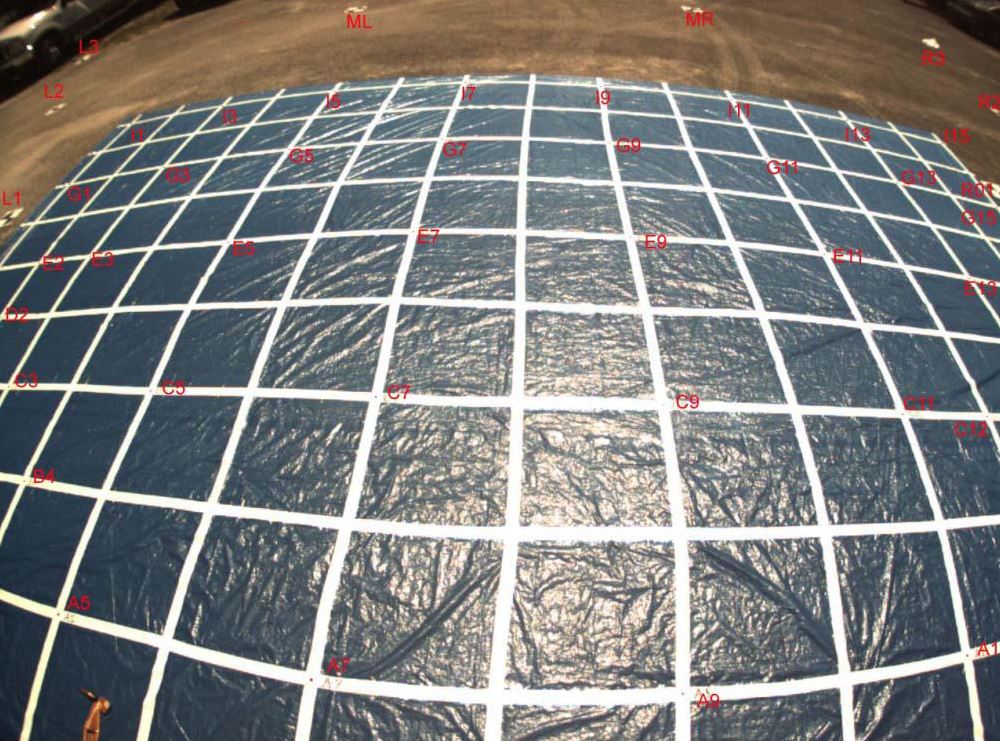

The SSMC team has developed a more efficient methodology to rapidly locate features onto the map. Each camera is calibrated with respect to its lens configuration and orientation on the vehicle. A test pattern is set up and image calibration points are located on the test pattern. For example, in the image below, the camera calibration grid has been labelled with a series of calibration points shown in red.

The coordinates of the image calibration points are measured to establish the relationship between the vehicle and its orientation with respect to the features in the image located on the ground. This relationship of image coordinates to ground coordinates can be calculated as an image transformation to warp and flatten the original image onto the surface of the GIS map.

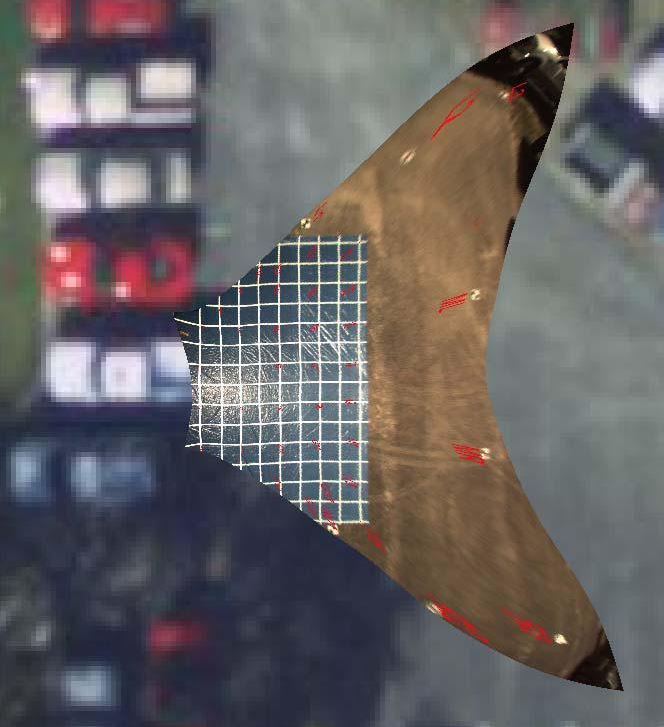

By applying this transformation to the image we can display the image in its true ground orientation on the GIS map to locate and measure the dimension of features on the ground. The image below shows the downward-looking camera image on the previous page after it has been warped to its actual position and orientation on the ground.

Since the cameras remain at a fixed orientation relative to the image collection vehicle throughout the entire data collection part of the project. The SSMC team can apply this image transformation to any of the collected images and simply drag and drop the pavement image showing the distress onto the map for location and measurement.

For example, in the illustration above, the front and rear camera images have been dropped into the GIS map to locate and measure pavement distresses.

Once placed on the map, the image can be enlarged and extremely fine details can be seen, crack widths can be measured to determine distress severity and the distress can be traced on the map and linked to the PAVER database.

To draw the distress into the GIS database, the Pavement Distress Technician simply traces the limits of the distress or the centerline of the crack onto the map, and tags that distress feature to the appropriate paver section.

The following examples illustrate this production process:

Step 1: The Pavement Distress Technician identifies severe weathering and ravelling and a pavement patch in the forward camera image.

Step 2: A rear pavement image is selected that shows the distress.

Step 3: The rear image is dragged into the GIS map to warp and geo-reference the image to its proper position in the world.

Step 4: The Technician enlarges the pavement image and selects the appropriate distresses to be captured.

Step 5: The limits of the Weathering and Raveling is drawn and identified as Severe (as shown in red), and the limits of the Pavement Patch that fell within the roadway is identified as Moderate (shown in blue). These distresses are tagged with the ID of the roadway section and the areas of the distresses are automatically calculated for the PAVER database.

This visual GIS approach has three distinct advantages over other condition assessment methodologies.

- Accuracy: All distress quantities are accurately measured, not estimated.

- Precision: The network can be analyzed at the network level or you can drill down to see individual distresses. This allows for a thorough Quality Control Review of the identified distresses.

- Repeatability: The previously identified and tabulated distresses are already in the database for subsequent re-inspections of the network in later years.

Do you have questions about this case study?

Get in touch with NorPix, Inc, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

![Streampix-8[1].jpg](https://cdn.geo-matching.com/Vo1zXJ5R.jpg?w=300&h=300&crop=1&s=da12dc5361b5395de101ff7b79c48b94)

![Do-Giant-Tortoises-Make-Good-Neighbors-1[1].jpg](https://cdn.geo-matching.com/vRMO2Edp.jpg?w=320&s=a6108b2726133ff723670b57bc54c812)