Intelligent Solar Energy Inspection Project Using Lidar and Point Cloud Data

Known as solar power plants, solar farms, solar parks, and photovoltaic power stations or plants, photovoltaic systems (PV systems) have become larger and more significant, increasing in construction and scale during the past decade. Although, Photovoltaic power operations and maintenance challenges have become more prominent and frequent. Traditional manual inspection can encounter many problems, such as inefficiencies, non-standard data collection, and a poor operating environment. Faced with these difficulties, using an intelligent inspection system, UAV-based LiDAR has become one of the most effective solutions.

Project Outline

The project mainly focused on inspecting 110kV boost stations and solar stations (field area) using Lidar technology. By adopting lidar technology, point cloud data collects and creates 3D spatial structures of a solar power facility and is conducted through high-precision route planning. Through UAVs are equipped with different sensors, details from each solar panel and other power generation equipment can be taken from all directions after one flyover. The data obtained is analyzed by an AI image processing system (AI Image Intelligent Analysis System), and a report is generated.

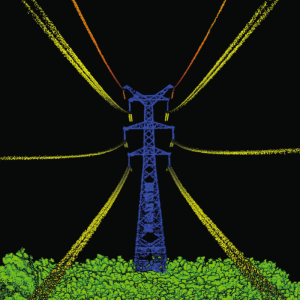

Lidar Scanning and Modeling

Preliminary route planning for the survey area, the UAV-Based Lidar System LiHawk collects point clouds of the photovoltaic power station (solar farm), transmission lines, transformers, and other equipment. LiAcquire solution software uses raw data to calculate high-precision trajectories, providing the user with route planning information (point cloud data).

The collected data points will be used as the basis for future planning and inspection routes.

|

UAV Platform |

Diagonal Distance |

160cm |

|

Weight (Include battery) |

16.5kg |

|

|

Payload |

8kg |

|

|

Hovering Time |

120min(No payload) 40min(Payload) |

|

|

Hovering Accuracy (P-GPS) |

Vertical:+/-0.1 m(Visual orientation);+/-0.5 m Horizontal:+/-0.3 m(Visual orientation);+/-1.5m |

|

|

Max Wind Resistance |

10m/s |

|

|

Lidar |

Laser Product Classification |

Class 1(Eye safety) |

|

Measuring Range |

0.3-1350m |

|

|

Field of View |

330° |

|

|

Measurement Rate |

750,000 pts / sec |

|

|

Accuracy(Elevation) |

<10cm(200AGL) |

|

|

Echoes |

Unlimited times |

|

|

Attitude Accuracy |

0.005° |

|

|

Weight |

4.35kg(Include camera) |

Route Planning

Data Acquisition

Inspection Equipment

|

H20T-Quad-Sensor Solution |

||

|

Supported Aircraft |

Matrice 300 RTK |

|

|

Zoom Camera |

Sensor |

1/1.7" CMOS, 20 MP |

|

Photo Size |

5184*3888 |

|

|

Wide Camera |

Sensor |

1/2.3" CMOS, 12 MP |

|

Photo Size |

4056 x 3040 |

|

|

Thermal Camera |

Sensor |

Uncooled Vox Microbolometer |

|

Digital Zoom |

1x, 2x, 4x, 8x |

|

|

Image Resolution |

640×512 |

|

|

Scene Range |

-40 °C to 150 °C |

|

|

Laser Rangefinder |

Measurement range |

3-1200 m |

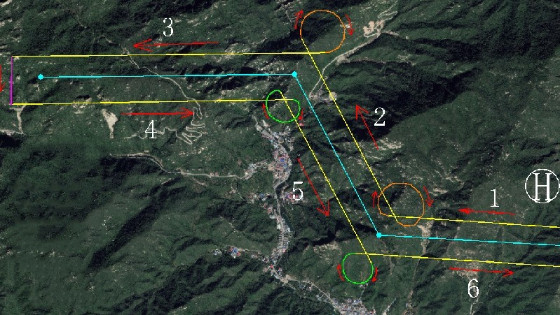

Inspection Route Planning - Examples

Inspection Route of the Solar Power Station (PV System)

Inspection Route of Solar Panels

Inspection Route of Booster Stations

Inspection Route of Power Lines

Sample Inspection Results

Computer Vision - Intelligent Analysis System

Based on multi-source (visible/infrared) data, the system combines expert knowledge with artificial intelligence to accurately analyze the visual and infrared data. The system determines the type of flaws found and their impact on power generation efficiency. It provides a supporting reference point for the operation and maintenance at the power station.

(1)Multi-Defect Detection of PV System Modules Based On Visible Light

Using a visual recognition algorithm, the visible light images are analyzed and identified. Defects are found in time, the problem locations are logged, and a diagnosis report is automatically generated. The report is sent to the operation and maintenance personnel within the photovoltaic power station.

(2) Defect Detection Based on Infrared

Using infrared cameras, the deep learning model identifies hot spots and foreign object occlusion in diodes, generating a comprehensive analysis report.

Do you have questions about this case study?

Get in touch with GreenValley International, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

![Do-Giant-Tortoises-Make-Good-Neighbors-1[1].jpg](https://cdn.geo-matching.com/vRMO2Edp.jpg?w=320&s=a6108b2726133ff723670b57bc54c812)