Offshore Survey with an Autonomous Vessel

Recently at a HYPACK meeting in Oregon, the discussion turned to the effect that the maritime environment has on global commerce. It is enlightening to learn that most of the world’s population resides within 100 miles of an ocean or a sea, however, many people are unaware of the role water plays in the transport of the goods they require. It is estimated that 80% of all goods are transported by water at some point between production and delivery to the end customer. The largest port in the US is the Port of Los Angeles, and together with its close neighbour the Port of Long Beach they handle over 20 million TEUs (twenty-foot equivalent units) per year, yet the Port of Los Angeles is only the 9th largest port in the world.

Project Summary

• Effectively collected multibeam data of anchorage in Boston Harbor with an autonomous vessel.

• Reduced survey turnaround time by automatically transferring collected data in time-limited packets to a remote processing team all while the survey was being conducted.

Products Used

• OARS Pod

• Applanix POS MV

• HYPACK® Software

• Teledyne T20 MBES

• Sea Machines SM300 Autonomous System

• Survey Equipment Services Survey Sensors

The safe handling of all of that cargo requires current, up-to-date knowledge of the depths around each port and its shipping lanes. According to the Centers for Disease Control and Prevention¹, there were around 67,000 workers employed in the US water transportation industry in 2016. Around 26,000 of them work in the inland waterways. From 2011 through 2017, there were 87 fatal injuries, averaging 18.4 deaths per 100,000 workers per year across this period. This is nearly 6 times the rate for US workers in all professions. In the same period, there were around 11,000 non-fatal injuries in the industry. With this as a background, the surge in autonomous survey vessels in recent years is quite understandable. Autonomous vessels reduce the risk of injury to personnel and crew fatigue while enabling operations in conditions where crewed vessels may be unable to work.

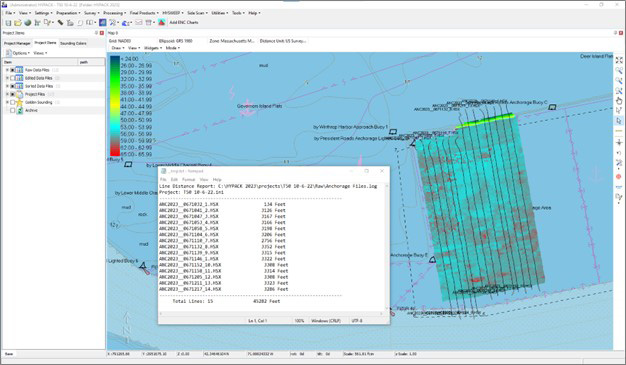

The survey area covered 5 million square feet and required 8 line miles of survey.

As part of this growing trend, a group of companies came together to conduct an offshore survey of the anchorage near the entrance to the Boston Harbor with an autonomous vessel. For this survey, the vessel travelled 8 line miles to cover over 5.5 million square feet and operated over 5 nautical miles from the control room. The entire survey was conducted in just over 2 hours including data processing.

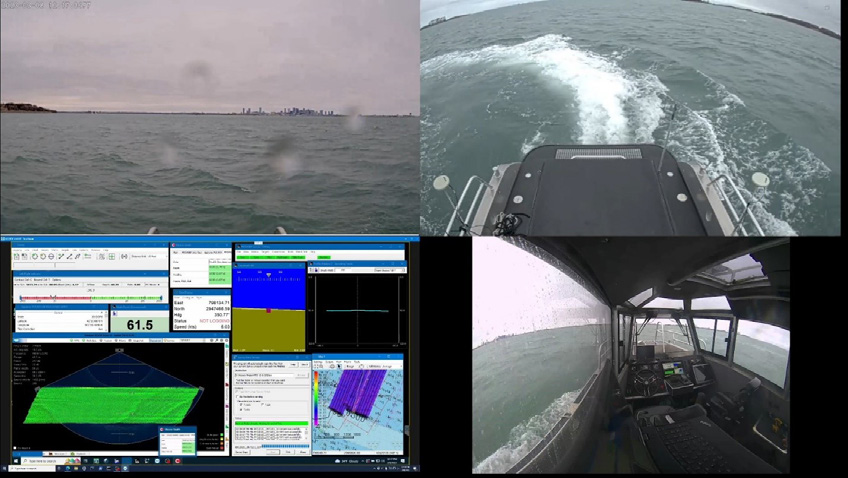

Sea Machines provided the vessel, which was controlled by their SM300 Autonomous Control System. The vessel was commanded and monitored from the Sea Machines control room in Boston. Connectivity is always important in a remote operation, and so we used 4G internet for our survey. Having such a strong connection to the vessel enabled real time streams from the vessel cameras, radar, and AIS, making situational awareness feasible. In the office, the assortment of displays allow the operator to simultaneously monitor multiple views.

Survey Equipment Services provided the survey sensors with onsite installation assistance from Gary Sayers throughout the project. A Teledyne T20 MBES along with an Applanix POS MV were used for the survey.

Autonomous vessel piloted by the Sea Machines SM300 autonomous system.

The main challenge we had to address was the ability to collect, process, and turn a survey around as quickly as possible using the autonomous platform. To facilitate this, the 4G internet connection provided access to the onboard computers. A lot of time and attention was spent setting up the system to upload a survey directly from the vessel, since the sooner the data is available to operators, the sooner the survey could be viewed and a decision made about its quality.

In many cases, the data collected during a survey can only be processed once the vessel returns and the data can be offloaded, which adds downtime we want to eliminate.

For our survey, the data was collected on one PC and then transferred over an internal network to a network storage device accessible to anyone on the network. However, a key issue was the size and amount of data uploaded over the internet connection.

Simultaneous video streams along with HYPACK Survey enable situational awareness from the remote control room.

HYPACK® software was configured to create a new file every 15 minutes of survey. Having the 15-minute limit on files controlled the size of the collected data to a manageable amount for transferring over the network or even off the ship. The size of the files can be reduced for lower-bandwidth situations. Once a file reached its 15-minute limit, it was closed and transferred across the network for processing and a new file was opened to continue data collection. The transferred file was processed onboard the vessel by the remotely located OARS team. This method reduced the amount of time between file close to processed sonar data ready for use.

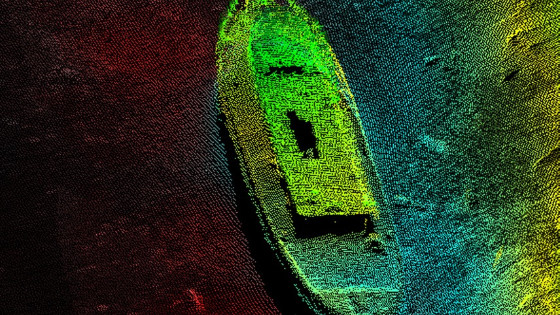

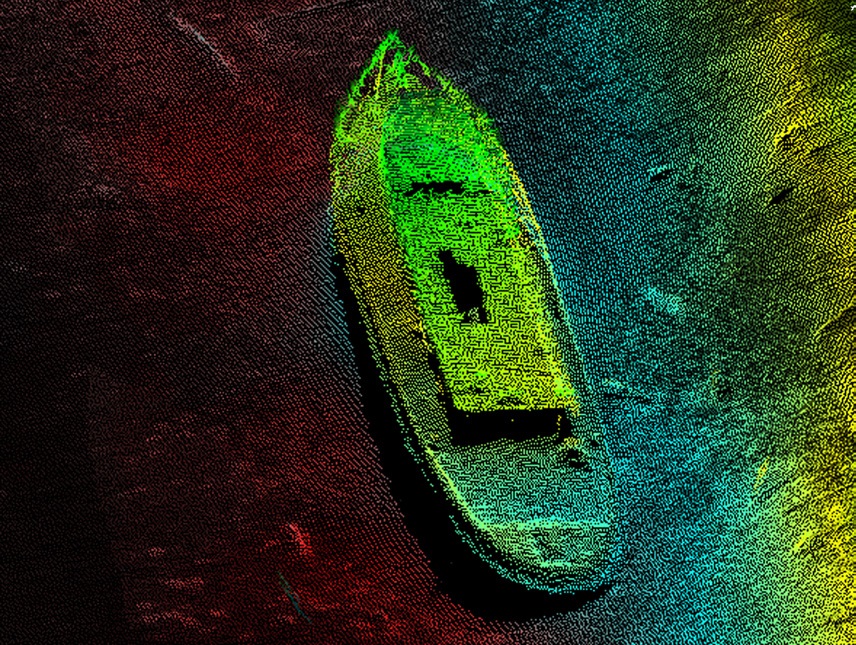

Survey data collected by a Teledyne T20 MBES and Applanix POS MV installed on the vessel.

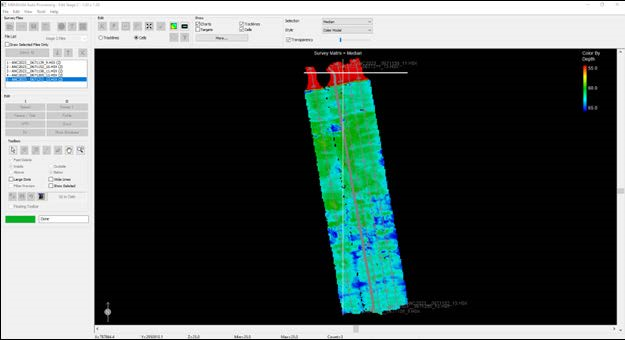

Using a sync program to synchronize two computers, the data can be transmitted off the vessel to a cloud storage location and onto the appropriate office. In this second scenario, the data would be available to any office node that is synched to the cloud storage. Meanwhile, in the office, the HYPACK 64-bit Multibeam Editor (MBMAX64) can be run in Auto-Process mode to apply filters and save the processed data without human interaction.

All surveys require human monitoring for safety and QC, however, the tasks of collecting and processing a survey can be extensively automated. In this collaboration with Sea Machines, setting up the autonomous vessel to automatically send packets of data to be remotely accessed allowed us to simultaneously survey and process data, increasing personnel safety while cutting down survey turnaround time.

Data processed in HYPACK’s 64-bit Multibeam Editor in Auto-Process mode.

Do you have questions about this case study?

Get in touch with HYPACK, A Xylem Brand, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

![Do-Giant-Tortoises-Make-Good-Neighbors-1[1].jpg](https://cdn.geo-matching.com/vRMO2Edp.jpg?w=320&s=a6108b2726133ff723670b57bc54c812)