3Dsurvey mission: Mobile photogrammetry development

For several decades, our cities around the globe have been getting bigger, more complex, more populated, and smarter, and so is the infrastructure. In this fast-growing tempo, government and local authorities are struggling with collecting the data in order to keep city planning and infrastructure changes under control. In this quest, surveying is for sure one of the most important services that help achieve this quest. And it does so with the help of photogrammetry. It provides proper data, which can be later processed and calculated to avoid all the possible issues.

How do we collect this kind of data with photogrammetry?

The traditional way is one of the options. Traditional measurement (GNSS, tape, stick) is accurate, but it is also extremely slow and by the time you measure something and draw the plan, there is a new crossroad already built across the street and what you have done is already outdated. Now, we have two options:

a) We could do it with a terrestrial photogrammetry process or with a mobile laser scanner, but the prices of that start around 50.000,00€ and that’s a bit much for a small land surveying company, right? That’s why we have to find a simple and fast mapping solution for urban areas and the critical infrastructure. Keep reading if you want to know what it is…

b) Of course, we know lidar scanning, which is used in other forms such as with helicopters, aircraft, drones and also terrestrial and mobile. The last two options are often used for mapping roads, because there's an interest in digitising traffic and municipal infrastructure and detecting damage and anomalies. But hey, are you allowed to fly in the city centre?! Probably no, so in this case of lidar vs photogrammetry, the latter is clearly the winner.

So how should we acquire the data accurately, easy and fast with minimum effort?! There are a lot of options on the plate, unfortunately all of them are expensive or forbidden by law. But as you know, 3Dsurvey is all about simple (and cheaper) solutions. So we went out and started our mission. This is a short story about our development of mobile photogrammetry software.

1. First steps toward our mobile photogrammetry solution

As we are developing photogrammetry software solutions for more than a decade, we believe we know a lot about drone photogrammetry. Being pragmatic and assuming that if it works with drones, it will also work with a car… We tested it out!

The idea was to acquire images with telemetry and the easiest way was to do so was to use an RTK drone. So, we mounted a Phantom 4 RTK with two additional video cameras Blackmagic with camera lens 7Artisans - fish eye on the car roof. The cameras were connected to displays and car power outlet. Before we started, we set the cameras to 1 second rounds and turned on the drones.

We drove down the road and took pictures with drones and cameras. Then we downloaded the images to the computer and processed them with the 3Dsurvey surveying software and the results were amazing. Really!

From the video and processed data it looks like a really easy job, but in fact, we had several iterations of this and we were trying out all sorts of possible combinations of shutter speed, camera angles and driving speed. We also had a lot of challenges with synchronising the data between cameras and positioning devices. We also had some issues when collecting the data on the fly and with the accuracy of the data acquired. There was some deep learning involved. But as you can see from the pictures, we definitely managed to create a prototype that really works!

2. Results of our study and next steps

We now knew exactly what photogrammetry hardware we need, how to set up the hardware configuration, synchronise devices, what the best shutter and location settings are and how fast we can drive. The question that was left open is: do we really want to play as a hardware vendor on the market? Do we want to deal with photogrammetry hardware production and distribution? The answer was NO. We are the (best) surveying software guys.

3. Who seeks (photogrammetry hardware) will eventually find - in Hungary

Therefore, we made the next step, looking for companies that are using a similar approach as we did and are manufacturing these devices. We found a young enthusiastic Hungarian team who already developed a similar device. No questions asked, we drove to Budapest to find out the details of their offering.

Their device is simple and efficient. It consists of a robust and durable construction, 2 high resolution cameras, INS module and 2 GPS antennas with RTK receiver, mysterious black box and controller. Great job, Hungary! Read more to see how we tested it.

4. The roadrunner test and results

As we are surveyors, we are always allergic to results that are not accurate, and of slow measurement processes, as we want everything fast, accurate and simple!

Using the roadrunner for a day, we measured and tested that:

- The horizontal positional accuracy of the test point cloud was on average 10 cm compared to validation points

- The vertical positional accuracy of the test point cloud was on average 12 cm compared to the validation points.

- The validation points were measured at the beginning and at the end of the measurements.

- Better accuracy of up to 4 cm is required, which we were able to achieve by setting ground control points every 200 m on each side of the road.

Using “roadrunner” for collecting information about municipal infrastructure and detecting damage and anomalies, is simply perfect. The device was exactly what we wanted to get with additional excellent support from their development team. We were driving around Budapest, testing the device and only after 48 hours decided that we want to make it a part of our mobile mapping solution.

The final result of our mobile photogrammetry mission

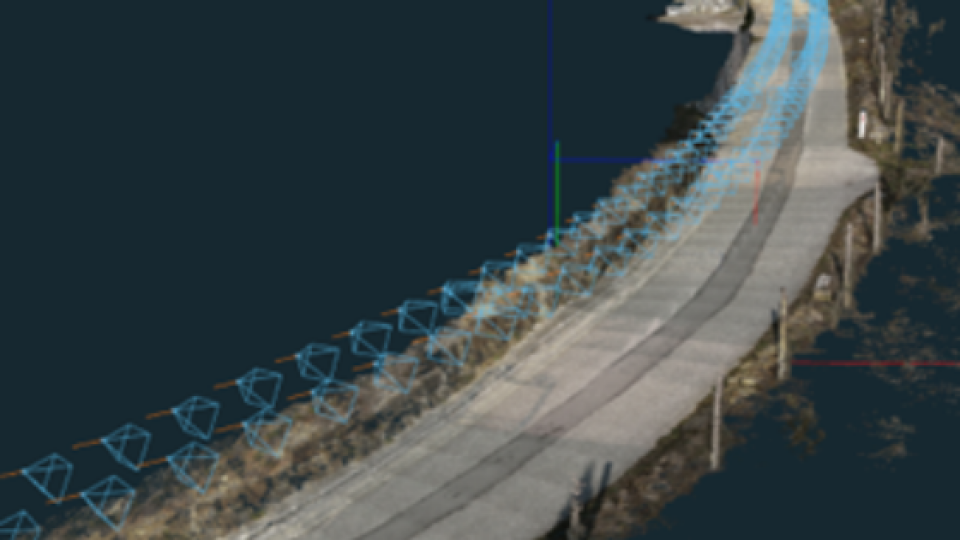

Below, you can see the point cloud made by a mobile photogrammetric device and how cool it is. We surveyors always strive for accurate data. Accuracy and precision are the most important to us. With the “roadrunner” we achieved quite good results. The horizontal positional accuracy of the test point cloud was on average 10 cm and the vertical 12 cm compared to the validation points. The validation points were measured at the beginning and at the end of the measurements.

“Roadrunner'' is a perfect photogrammetry hardware for collecting information about municipal infrastructure and detecting damage and anomalies and with 3Dsurvey photogrammetry software it’s a perfect match! For land survey maps, a higher accuracy of up to 4 cm is required, which we were able to achieve by setting ground control points every 200 m on each side of the road and some other tweaks (we will talk about them in on of our future blogs so stay in touch).

Do you have questions about this case study?

Get in touch with 3Dsurvey, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

Related products

![Do-Giant-Tortoises-Make-Good-Neighbors-1[1].jpg](https://cdn.geo-matching.com/vRMO2Edp.jpg?w=320&s=a6108b2726133ff723670b57bc54c812)