3D Guidance and Visualization Systems Are Improving Marine Construction Productivity

As the global economy continues to improve and populations advance in the coastal areas around the world, the demand for commercial dredging services and efficient marine construction capabilities are increasing at a steady pace. Future Market Insights (FMI) tells us the dredging market will grow to nearly $16.5 billion by the year 2022*. Part of that growth comes from key drivers pushing the dredging industry including the global demand for energy, water-related tourism, and as coastal protection and environmental sustainability efforts.

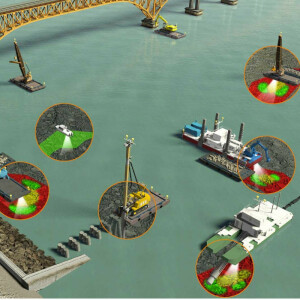

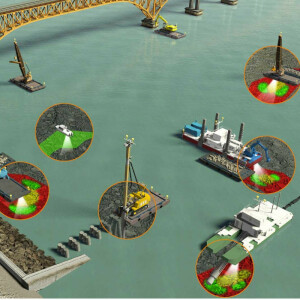

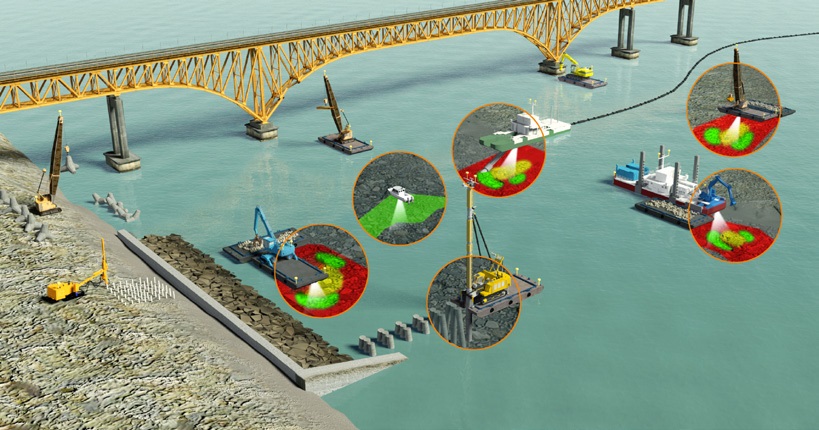

Marine visualization software components

Gaining greater predictability, precision and profit for construction and dredging projects

Dredging and marine construction work need to be predictable and precise in order to be profitable. Having the right team of operators and project managers coupled with the right marine construction technology can accelerate and enhance performance while giving contractors a competitive edge.

Accurate marine positioning technology and 3D visualization systems are both critical because they can help contractors avoid spending excess time and money on dredging, dredging outside the plan or performing rework that may involve the expense of returning equipment to the site. Not only can marine visualization systems help companies better compete in tight margin projects, but the software’s documentation and reporting capabilities can instil confidence that contractors are delivering and reaching the depths promised in a timely and expected manner. Marine contractors can get paid precisely for the amount of material moved, with support from data-driven reports and visual documentation, giving the contractor and client peace of mind. Leading 3D visualization systems can support a breadth of applications and dredging and marine construction operations, including:

Dredging

► Backhoe/excavator dredger

► Grab/clamshell dredger

► Cutter suction dredger

► Bucket dredger

Rock Dumping and Placement

► Caisson placement

► Block placement using wire crane or excavator

► Vertical and raked pile placement

Inspect, Repair and Maintain (IRM) Hydrographic Survey

► Single beam hydrographic survey

► Multibeam hydrographic survey

Marine contractors looking to keep ahead of these pressures and capitalize on new opportunities are turning to next-generation marine construction visualization systems to

help improve the accuracy, efficiency and speed of dredging, piling, placement and hydrographic surveying workflows. The latest generation of innovative 3D visualization applications is significantly improving the accuracy of dredging and surveying by empowering the operator to work smarter and to avoid rework.

These new tools allow the operator to ‘see’ the design and the dredge tool in real-time relative to the waterway bed, all from an onboard display inside their cab. These systems are now providing precise measurement, positioning capabilities, and 3D visualization and in doing so, they are considerably improving marine construction productivity, efficiency and safety. Applications for today’s marine construction visualization software include projects such as dredging, caisson placements, building breakwaters, piling for wharfs/piers, rock dumping, and excavating, as well as hydrographic applications such as surveys, or tracking dredge progress.

Tasks such as project planning, estimating and bidding, project monitoring and client communications are all enhanced with the 3D visualization technology. This article will highlight considerations for selecting next-generation 3D marine visualization systems, primary benefits and ROI potential, as well as strategies around implementation.

Track work in progress

At the heart of 3D visualization capabilities is marine construction software that provides real-time visualization of the dredge tool showing the operator the actual versus planned surface being constructed. Depending on the scope of their business, contractors should select software that can be used effectively with a variety of dredge tools, from standard buckets to clamshells, dredge pumps, cutter suction dredge heads

and more.

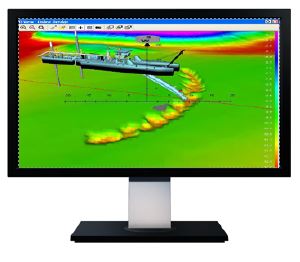

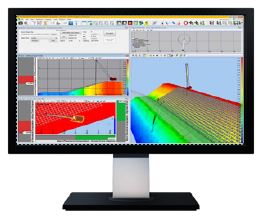

Advanced real-time 3D visualization applications available today are helping marine contractors and dredge operators improve productivity and efficiency at every level. With visualization technology the operator has a real-time view of the dredge and barge in plan and profile views. For an excavator dredge, the position of the bucket relative to design is tracked continuously and displayed. A color-coded Digital Terrain Model (DTM) highlights the high and low spots compared to the design. The model is updated in real time from the position of the bucket teeth and the bucket width, which, as a result, tracks the progress of the dredging work.

The surface DTM is updated registering the development of the dredging work showing depth, differential and production models according to the progress of the bucket.

For the engineer, projects that require an extra level of confidence and data validation, look for systems that support real-time sonar inputs for as-building capabilities. Combined with sonar technology, dredging companies, and those focused on hydraulic engineering, construction, offshore and survey have an even greater underwater vision in the most challenging inshore underwater environments and conditions.

Visualization adds verification and improves safety

For the as-building capabilities of the system, having products available that will generate a 3D point cloud of the work or visualize the underwater structure will boost productivity directly. Seeing what is underwater in the proximity of the work or seeing the work will remove the need for intermediate inspections with ROVs or divers. Removing the diver from the project will also reduce the hazard for personnel working with the system.

Having a tool which can compensate for the motion of remote sensing devices will be beneficial. A construction barge can then be used for scanning an area without the need for a survey vessel. And improve productivity by removing the need for post-survey processing. Therefore it will be useful if the as-building capabilities are able to compensate for motion and georeference in real time. For instance a DTM can be made from the work at hand and can, in combination with a proper profile plot system, be used as a validation of the work done.

“Sonar technology along with 3D visualization systems give contractors a greater ability to inspect, maintain, repair and survey in real-time while on the jobsite, or remotely monitoring progress,” said Ted Germann of Teledyne. “They combine to provide an even clearer picture of what’s happening with dredging, marine construction and IRM efforts because it brings a verification phase to the process. Marine contractors should consider the ability to integrate sonar into their workflows with scalable 3D visualization software. Together they can provide a true competitive advantage by improving accuracy and reducing the potential need for rework.”

Real-time visualization and reporting

One of the benefits of using marine construction visualization systems is that machine operators can set over-dredge and under-dredge tolerances on the profile view of the dredge head. A 3D picture gives the operator an explicit visual representation of where they need to position the dredge head underneath the water, with a goal of removing material precisely according to the design as indicated on the onboard screen.

When comparing marine software systems, contractors should consider systems that provide real-time sensor data gathering, computation, display and logs. Options to display data either graphically or alphanumerically and to present the data in the form of models, tables, files, volumes, nautical charts or reports gives operators and managers instant access to project information in a form that is easy to understand and communicate with others in order to make more informed business decisions. The ability to calculate cumulative production and produce reports about dredge progress is important because it can help contractors meet and document benchmarks and keep operators focused on the task at hand. Reports that show progress by runline, operator or job, make it easy for project managers who are remote to see accurate progress and deliver project tracking reports directly to the customers for validation and payment. These capabilities enhance communication with internal teams while also strengthening customer communication and trust.

Selecting hardware components and accurate positioning systems

For marine construction visualization systems to work, they rely on advanced hardware components and positioning systems. Marine receivers and positioning sensors, accuracy starts with the GNSS receiver which can use corrections from a site base station or VRS to achieve high accuracy. Then precision is maintained via precise sensors on the dredge, barge, cranes, tugs and excavators are continuously feeding the software data for accurate roll, pitch and location information. Additional components include in-cab displays, surface viewing screens, GNSS receivers, pitch and roll sensors, and communications (e.g. Wi-Fi, radio or cellular). Excavator dredges also require angle sensors on the boom, stick and bucket.when a barge is used, it can also be fitted with a GNSS heading bundle and a commercial-grade Wi-Fi connection. These marine receivers and positioning sensors provide the ability to monitor tidal and other water level changes in real-time. Today’s most advanced dual-frequency, real-time kinematic (RTK) receivers deliver precise dynamic positioning with 20 mm (1”) accuracies, 20 times per second with a latency of less than 20 milliseconds.

Depending on the accuracy required, these receivers receive corrections from a traditional base station or other sources such as a virtual reference station. When evaluating options, it’s also imperative for contractors to consider whether they need a permanently installed GNSS heading and positioning solution, or if they require a flexible system that can be quickly transferred and deployed to different vessels. Some contractors prefer to future-proof by choosing systems that prepare for future projects or take advantage of the full feature set as they improve their skills.

Software, hardware, training and support

Conventional marine construction technology, including marine sensors and other hardware components, have in the past been notorious for having connection failures, downtime, or other related issues. Today however, modern systems are much more reliable and robust. Consistent uptime from every sensor and 3D visualization component is necessary in order to collect accurate data and to ensure enhanced production over the life of the project. Historically, it was common for contractors to rely on a piecemeal approach where they purchased hardware, such as sensors, from different manufacturers. In most cases, each vendor had a proprietary software package for hydrographic survey, design and data analysis. This implementation strategy presents challenges because it requires operators to learn various software packages from multiple manufacturers, and it increases the risk of project-stalling compatibility problems with file formats and workflows. Today’s leading marine contractors are opting for a more integrated implementation where they deploy marine-specific hardware and software from a single vendor. This eliminates the potentially costly risk of integration challenges that can cause slowdowns or missed opportunities. Also, when components are deployed from one manufacturer or partner, they share a standard interface. In these cases, users

can reuse data and accessories across multiple applications much more efficiently and those integrations are already built to work with existing hardware and workflows. For operators, and training managers, they can spend less time training and more time getting work done, as the software similarities between workflows make it easy to transition..

Visualization must haves - 3D onboard displays

Today’s advanced 3D marine visualization systems also include an in-cab display and surface viewing screens. These components give operators a real-time overview of the excavator and barge in multiple views. Compared to conventional 2D marine software capabilities, today’s 3D systems can accurately display and record complex design surfaces and a 3D display of the bucket as it breaks the seabed surface. This capability is critical because it guides the operator back to the last dig each time work begins. This is an essential feature when projects take place over several weeks or when machines need to stop at designated times to keep shipping lanes clear. During the selection stage, it’s crucial contractors look for systems that can process large data sets from multibeam progress surveys to more clearly and effectively show the updated dredge surface as the job proceeds.

Displays should also be customizable giving lead engineers the ability to set up the screen to meet their exact preferences and to sync up with existing workflows. Look for displays that have larger screen resolution and clearer screens that enhances operator experience 2D and 3D profile information, grade guidance, and warnings. Keep in mind that displays that keep it simple for the operator, help them focus on the task at hand, while providing adequate warnings and other indicators to help them be aware of other critical environmental conditions.

Environmental auditing

In environmentally sensitive or high-profile projects, your customer may request additional progress reporting as a communication tool to relevant stakeholders, The system should be able to provide easy-to-understand graphs, maps and tables to update the project manager and ensure that stakeholders are informed of any changes or work completed around sensitive environments. Reporting capabilities tied directly into the visualization software and guidance technology can streamline the reporting process allowing project managers to create volume reports and other status reports directly to keep all stakeholders up-to-date on project progress and aware of any changes or sensitive environmental conditions, as needed. Staged implementation, local installation and training support When considering which system to choose, make sure your business is covered with local service and support from a trusted supplier.

Your local dealer can offer selection advice, calibration and training for your operators, as well as technical support, and spare parts. If your projects are interstate or international, make sure that your supplier has local representation as well.

It may also be important to talk with partners about their recommendations around a staged implementation approach. Marine construction systems can be more powerful than some contractors have need for in their first deployment. Contractors not familiar with the full feature set, may wish to focus on the benefits of accurate dredging and placement to begin, then as users become more familiar with the system, they can evaluate other benefits including 3D sonar verification, for example.

Return on investment (ROI)

When considering marine construction systems, consider the payback in terms of improved accuracy, uptime and preventing problems before they happen. For a harbor dredging project, it should be able to achieve vertical accuracy to +/- 100 mm (4 inches). When multiplied across the area of a harbour, this improvement in accuracy, can quickly add up to hundreds of thousands of dollars. Reducing or eliminating the amount of rework needed on a project gives marine contractors the largest ROI payback potential. Any time an additional hydrographic survey is not needed, or additional fill material is not required or a machine does not have returned to site for rework, there’s the potential to save thousands of dollars and as a result, the profit margin on that project is maintained.

By tracking ‘as-building’ progress, contractors can avoid rework and the potential to return a machine to site after the survey when areas may have been missed or material has moved. Real-time progress reports, also provide an early indicator if the project will be delivered on-time.

Wrap up

As port infrastructures continue to expand, regular dredging is needed to keep shipping lanes open. On top of that, growing concerns about environmental protection and sustainability along with increased tourism also mean that coastal remediation and dredging efforts will continue to keep develop and maintain waterways and coastal areas.

With the right marine construction visualization system and implementation strategy, contractors involved with marine construction, hydrographic survey and dredging operations can expect substantial ROI in terms of increased dredging speed and accuracy, as well as reduced risk and improved jobsite safety. Improved documentation and validation capabilities from the software will also enable contractors to more quickly and accurately bid projects and track material movement. In this dynamic environment, marine contractors that take the right steps today will be uniquely positioned to play a pivotal role in not only building and shaping our global coastlines but also in developing better communities and a bright future.

Do you have questions about this case study?

Get in touch with Trimble Marine Construction, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

Related products

![Do-Giant-Tortoises-Make-Good-Neighbors-1[1].jpg](https://cdn.geo-matching.com/vRMO2Edp.jpg?w=320&s=a6108b2726133ff723670b57bc54c812)