Underground Mine Mapping and 3D Modelling with Portable Lidar System

The surveying of an underground mine is difficult for two orders of problems: the complicated and dark tunnels environment and the underground depth where GPS or GNSS signal can't be reached. The Aurantech company has faced this problem in an old underground mine site, in Zhejiang and thanks to the HERON wearable mobile mapping system the procedure for data collection was not only possible but also efficient.

After pre-processing the surveying acquisitions and filtering the noise, it was possible to build the surface model of the tunnel based on the required parameters, with a global accuracy of 10 cm. The data extraction has been made with JRC 3D Reconstructor software. First, the data have been aligned via the automatic registration and bundle adjustment software's functions. Then, the cross-sections were easily generated and volume and surface areas were computed on the 3D model. Finally, the 3D model was easily exported to third-party applications using one of the most common data interchange formats.

Fig 1. The operator with HERON AC-1 during the surveying activities in the underground mine

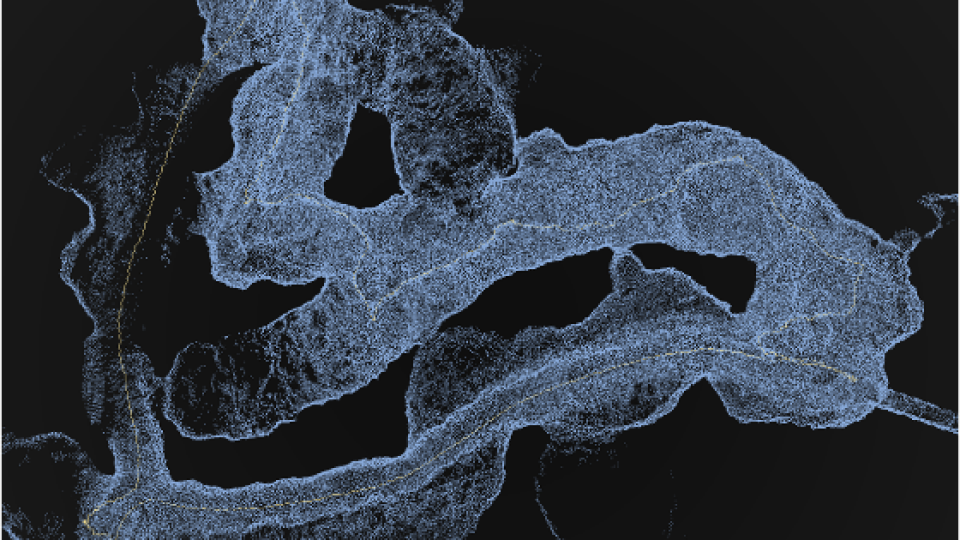

Fig 2. HERON point cloud model of the underground mine with the path

We had just set up some control points using a total station and then walked with HERON. Software and hardware made the work easier and supplied us with a complete solution. HERON is a reliable, simple and high-performance 3D solution

Sherry Wang

AURANTECH | Commercial Manager

Underground Mine Mapping Needs and goals

- Generate a precise map of an old tunnel where tripod laser scanners or GPS cannot be used.

- Build a measurable 3D model of the underground mine starting from the 3D point cloud.

Underground Mine Mapping Results

- 3D point cloud model

- Depth calculation

- Area calculation

- Cross-sections

- Volume calculation

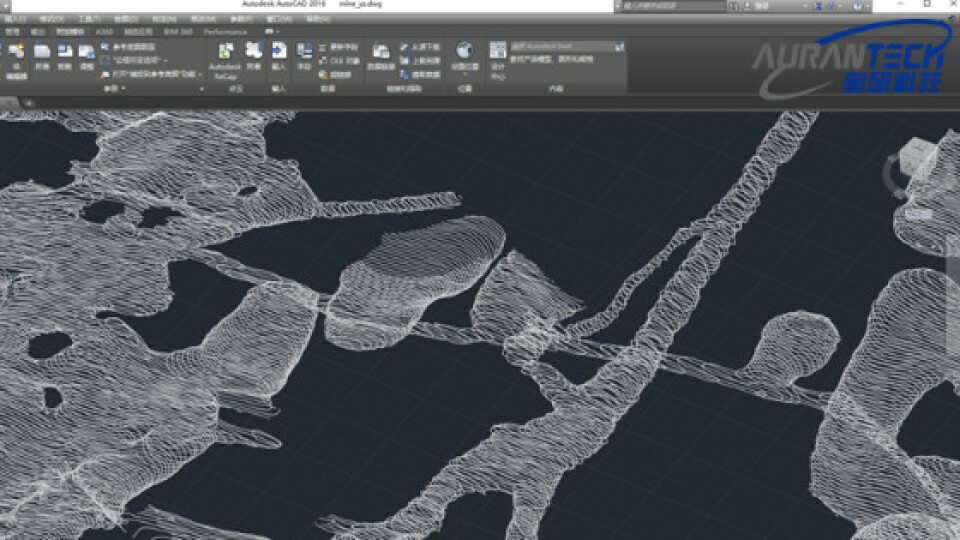

Fig 3. CAD environment: cross sections of the HERON point cloud model

Heron AC-1 main benefits

- Work without GPS or GNSS sensors

- Precision of final results

- Management of wide and different data

Underground Mine Mapping technical details

- SURVEYING SYSTEM: HERON AC-1 and total station

- SURVEYING AREA: 250,000 sqm abandoned mine

- SURVEYING TIME: 6 hours

- PROCESSING SOFTWARE: HERON Desktop and JRC 3D Reconstructor

- PROCESSING TIME: 18 hours

Do you have questions about this case study?

Get in touch with GEXCEL, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

![3月21日-封面[1].jpg](https://cdn.geo-matching.com/voeE1ywo.jpg?w=320&s=6b3b1a0215d770f8797653e9202a8f52)