Measuring Sub-bottom of the Port of Bristol

Port of Bristol’s conservancy manager and port hydrographer, Mark Burrows, tells about the UK port’s difficult hydrographic requirements and the equipment it relies on to maintain depths The Bristol Port Company (BPC) is one of the major ports in the UK responsible for handling a wide variety of cargoes that are essential to the country, from coal and biomass for power stations, to cars, jet fuel, and animal feeds. Cargo arrives in vessels of up to 130,000dwt and 14.5m draft and so it is vital that there is sufficient water for them to gain access to the port safely and efficiently to fit with global schedules.

The environment around the port creates certain challenges to operations and in the 20 years that it has been privatised, the company has invested in the best equipment to enable the port to perform at its best. The proposed construction of another terminal –

Bristol Deep sea Container Terminal – further heightens the need to ensure that all the port’s waterways remain navigable. The Bristol Channel and Severn Estuary combine to create an expanse of water that produces the third highest tidal range in the world at the port with currents that can reach Skts in the Inner Estuary.

The spring tidal range of 14.6m presents specific challenges for the Marine Department, which is responsible for monitoring access to the docks at Avonmouth and Portbury.

We have to maintain a continuous watch on seabed mobility and the density of the mud flowing over it. This means there is always plenty of work for the port’s 20m survey vessel /sambard Brunel, 7.9m Cheetah catamaran Investigator, and cutter suction

dredgers Ma/ago and Even/ode. One of the unique features of the upper Severn Estuary is the enormous quantity of suspended

sediment in the dock approaches that can often result in vessels sailing through what is essentially liquid mud. This presents the hydrographic team with three challenges:

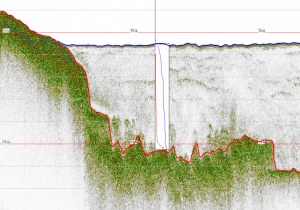

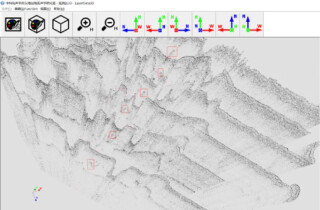

- To ascertain the depth and contours of the seabed using classic survey techniques with

modern equipment; - To determine the density of the suspended mud to ensure that the handling capabilities of the vessels entering the docks are not compromised, and;

- To manoeuvre lsambard Brunel in the dynamic, acoustically harsh and confined entrances to the docks with specialist over-the-side survey equipment measuring through the water column.

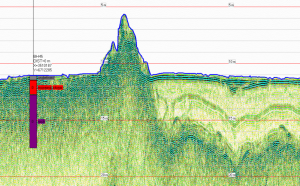

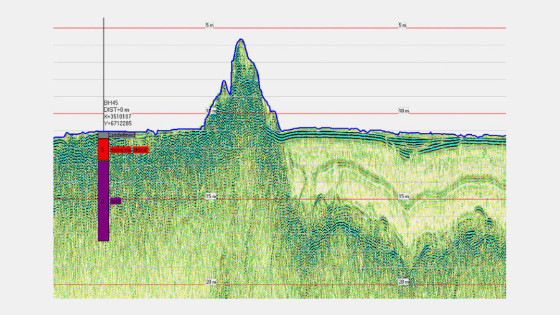

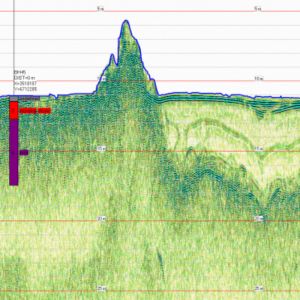

The fluid mud that gathers at the entrances to the terminals can form a layer several metres thick. A safe navigable mud to water ratio of no more than 1.2 tonnes per cubic metre (200,000 parts per million) of water must be maintained at all times and so regular dredging operations and density surveys are vital.

The density of the mud layers cannot be measured by conventional dual-frequency or multibeam echosounder surveying and it is for this reason that the Stema-Systems survey system was commissioned in 2002, and recently upgraded.

This system complements the onboard RTK (Real Time Kinematic) GPS and DGPS (Differential Global Positioning System), Atlas Deso and Reson NaviSound dual-frequency single-beam echo-sounders, Reson 8101 SeaBat multibeam echo-sounder, MAHRS and CMS25 motion sensors, both from Teledyne TSS, and a vessel-mounted Teledyne RDI Workhorse Mariner ADCP (Acoustic Doppler Current Profiler).

The Silas Acquisition program – part of the Stema-System’s suite – gathers the sensor data. This program is interfaced with Reson’s onboard PDS2000 navigation, acquisition, and processing software to give real-time data displays and track plots for the surveyors and coxswain.

The port has to survey the entrances about four times a month. It first does a single-beam profile (acoustic) survey of the seabed by running a dual frequency – 210 and 33 kHz – echo-sounder survey. We analyse this acoustic profile and then decide which locations to deploy Stema-System’s DensiTune probe (see box). Once the two sets of data – probe profiles with the single-beam acoustic data – have been gathered, we

integrate them to determine the density of the water.

This profile is then exported to the mapping software and subsequently plotted in a computer aided design program to produce charts for Port of Bristol’s Haven Master, pilots, and dredge crews.

The data enables us to target any accumulations of mud and direct the dredgers to these sites. The equipment that w e now use has greatly increased the amount of data gathered and improved our survey turn-around times. We can optimize the dredging program and it gives us the ability to extend the tidal window and provide access for more deep-draft vessels.

Watch Deputy Haven Master (Conservancy) Port of Bristol, Mark Burrows him telling about this method

![3月21日-封面[1].jpg](https://cdn.geo-matching.com/voeE1ywo.jpg?w=320&s=6b3b1a0215d770f8797653e9202a8f52)