How Laser Scanning Technology Benefits Mine Expansion

Maptek I‑Site technology has been instrumental in providing accurate and efficient survey deliverables across the Savage River iron ore operation.

Maptek I‑Site Studio and the I‑Site XR3 laser scanner have been put to good use at the Savage River magnetite iron ore mine in the northwest of Tasmania.

Grange Resources Limited owns and operates Australia’s largest integrated iron ore mining and pellet production business. About 2 million tonnes of premium quality iron ore pellets are produced annually, with plans to increase to 2.7 mt. The Savage River operation is set to continue until 2034.

History

Magnetite mineralisation was discovered at Savage River in 1887, however, for many years, interest centred on the copper and gold potential of the deposit.

Exploration in 1956 included ground and air magnetometer surveys, with diamond drilling in 1957 and 1959. In 1965 the Savage River Mines Limited joint venture was formed to develop the project. The Savage River Project was then operated for a 30-year lease.

Ownership changed several times and a mine plan developed in 1997 included completion of mining operations in 2009. In 2006 a feasibility study proposed to extend the life of the mine until 2023, and in 2009 Grange Resources acquired all interest in the mine.

Laser Scanning for Mining

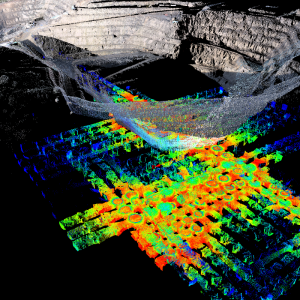

Three principal open pits - North, Central and South - are oriented north-south. They cover a 4 km strike length and are separated by unmined zones of thin or low-grade material. The pits average a depth of 100-150 m; the proposed cut back and extensions will deepen them by up to a further 250 m.

An exploration lease is held over another occurrence of magnetite mineralisation further south.

North and Central Pits are separated by the Savage River which runs through a pillar area left to retain the river channel. North Pit is mined using conventional off-highway rear-dump trucks and hydraulic excavators, with drilling and blasting to prepare the ground ahead of mining.

Grade control sampling is carried out on all blast holes within the orebody, as well as on selected holes on the periphery.

Savage River’s biggest challenge centred on conducting mine survey safely and efficiently.

‘One of the most productive and cost-effective decisions was to buy the Maptek I‑Site XR3 laser scanner and I‑Site Studio software,’ said Senior Surveyor, Michael Sadural.

Survey improvements with Maptek Laser Scanners

The I‑Site system streamlines survey compared to the traditional method using GPS and Total Station. UAV flights are contracted when required; they cover a wide area but are constrained by weather and the time needed for processing collected data.

Ongoing development of the project, and expansion of the pit by stages, meant that traditional mine topographic survey put even greater pressure on productivity.

‘We noticed an immediate difference as well as increased confidence arising from the implementation of I‑Site at our operation,’ Sadural commented.

Employing the I‑Site XR3 laser scanner to its full capacity highlights its ease of use and fast field acquisition. Accuracy and productivity has increased, with prompt survey deliverables across the Technical Services Teams.

Savage River now easily achieves weekly pit update, end of month pit and stockpile survey, fortnightly update of current dumps, main tailings dam topographic survey to update project development as well as volumetric survey of the Port Latta pellet stockpile and design conformance reporting.

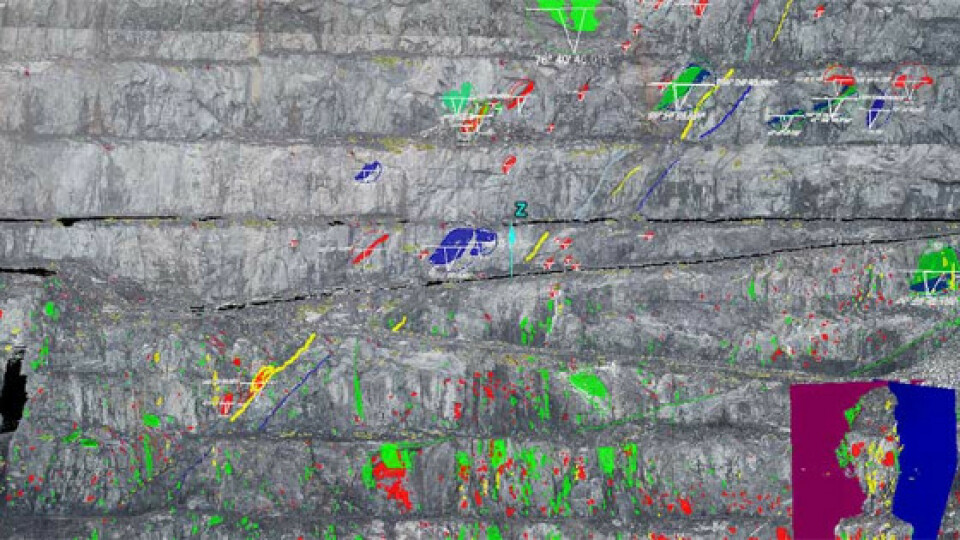

The system is also used to detect rock falls and wall movement, and to assist the Geotechnical Team with site geotechnical and structural mapping.

Mine Expansion with laser Scanners

The Maptek system overcomes the challenge of providing accurate and efficient survey deliverables for a wide range of operational requirements.

The Savage River survey team has welcomed the positive feedback received in response to significant improvements in daily processes.

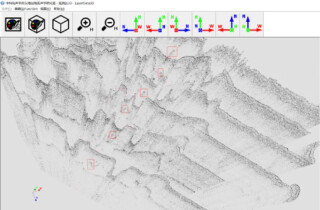

Savage River uses the vehicle-mounted stop and go survey method as well as tripod setup. The I‑Site XR3 laser scanner is robust and environmentally sealed to stand up to the harsh conditions on the mine site.

The dedicated I‑Site Studio workflow for processing and reporting survey data straight from the field includes QA checks on scan registration to verify results. User friendly and powerful software tools process point cloud data and generate accurate 3D models to update mine plans.

The latest scanning technology offers Savage River multiple benefits. The operation is now exploring further ways to progressively leverage a more productive and cost-effective total survey solution.

![3月21日-封面[1].jpg](https://cdn.geo-matching.com/voeE1ywo.jpg?w=320&s=6b3b1a0215d770f8797653e9202a8f52)