Trimble Precise GNSS/RTX Positioning Technology Brings Accuracy and Productivity to a Wind Farm in South Africa

Energy developers are tapping rich resources for wind and solar energy in the northern reaches of the Republic of South Africa. The work is fueled by the country’s drive to increase the use of renewable energy. In 2015, renewable sources in South Africa produced roughly 1,700 megawatts of electricity. The government wants to increase that number to 6,000 megawatts by 2020. The strategy is creating new opportunities and challenges for South Africa’s surveying professionals

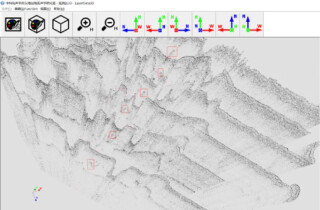

Working with the national electric utility, independent power producers are building large wind and solar farms. Leveraging recent work to electrify South Africa’s rail system (which effectively expanded and modernised parts of the national electric grid), new farms can be built quickly and readily connect to the grid. In the province of the Northern Cape, planning for the Khobab Wind Farm included determining the location for 61 large wind turbines capable of powering 120,000 homes. In addition to the turbine locations, planners defined the service roads, substations and power lines needed to build the wind farm and the 25 km connection to the national grid. Khobab developers selected Cape Survey Ltd., a Cape Town-based surveying firm, to provide essential services for the project. Before construction could begin, Cape Survey needed to define the easements and rights-of-way for the land use agreements and servitudes associated with the project. They would also install control points for the construction crews by setting points at roughly one- to two-km intervals. South African regulations called for required accuracy of 10 cm; the construction control points were provided with an accuracy of roughly 2 cm.

CHALLENGE

Cape Survey conducted initial surveys in 2014. While the Khobab site provided excellent conditions for GNSS, its remote location made it difficult to achieve the required accuracy and ties to South Africa’s reference system. There was no connection to cellular service, and the nearest survey reference station was more than 100km away. Ian Thompson, a professional surveyor with Cape Survey, said his team used post-processed static and real-time kinematic GNSS for the initial work. To create accurate control points, Thompson used Trimble R7 and R8 GNSS receivers for long-observation sessions. He processed the data using Trimble Business Center software to produce precise coordinates tied to the South African reference system. Cape Survey crews then used RTK to locate key points and to set out locations for planned roads, towers and other facilities. The R8 and RTK was the best tool for the job, but Thompson’s team could not move as quickly as they wished. The gently rolling terrain often blocked RTK radio signals, and regulations on radio output power further reduced performance. As a result, the team’s RTK range was limited. They frequently needed to create new control points and move the RTK reference stations to cover the 25km x 30km site. Each move took at least an hour out of their already busy days. While RTK provided the needed accuracy, it was a difficult process for this remote project. Knowing they would be working at Khobab again, Thompson needed a better solution.

THE SOLUTION

As the Khobab Wind Farm neared completion in 2017, Cape Survey was called upon to verify the as-constructed locations of the farm’s roads and power lines. The information would be used to finalise the servitude documentation. While Cape Survey would need to collect fewer than 50 points for the documentation, Thompson knew from earlier experience that the work would be challenging. He budgeted three days for the job. The Cape Survey crew arrived at Khobab equipped with a new Trimble R2 GNSS receiver and a subscription to Trimble CenterPoint® RTX positioning service. The Trimble R2 and CenterPoint RTX provided precise real-time positioning without the need for RTK base stations or cellular connection to the Internet. Using the Trimble R2 with a Trimble TSC3® controller running Trimble Access™ software, the crew initialised their survey and began collecting points. They checked into the 2014 control points with good results and used the points to calibrate precisely to the project grid. Because they could work without ties to an RTK base, they could move freely—or as fast as the deep sand and rutted roads would allow.

RESULTS

Instead of the three days planned for the work, the Cape Survey collected all the needed points in just one day. The time savings made everyone happy—especially the surveyors. Instead of spending two nights in very uncomfortable accommodations—Thompson said they would have slept onsite in shipping containers—the crew returned to their homes. In addition to the Trimble R2, the team also carried their Trimble R7 and R8 receivers, which would be used for RTK if needed. But the backup wasn’t required, so the team set up the R7 and R8 to collect raw data on two project control points. Thompson later processed that data with data collected onboard the roving R2. He used post-processed kinematic (PPK) techniques to double-check the RTX positions. “The RTX compared very well to the PPK results,” Thompson said. “We were consistently around 20 mm accuracy.” He added that the CenterPoint RTX solution initialised in 15 to 20 minutes and could be done while driving to the first points. Once converged, the satellite-delivered RTX solution could be held as the team moved around the site.

The Cape Survey team and their clients were impressed with the performance of the R2 and RTX services. In addition to cutting the time on-site by two-thirds, the system’s accuracy consistently exceeded the project requirements.

“The value of the system is clear,” Thompson said. “On this one job, we’ve more than paid for the year’s subscription to RTX.”

Thompson said that the CenterPoint RTX solution provides accuracy in approaching RTK without the need for additional equipment and processes. Cape Survey crews no longer need to carry RTK gear when working in remote areas. They are confident that the Trimble solution will provide the necessary accuracy and reliability.

“The main thing is time and cost savings and the consistent availability of the signals. Field time is cut dramatically, and we can use smaller crews.” IAN THOMPSON Professional Surveyor, Cape Survey Ltd. Cape Town, South Africa

Do you have questions about this case study?

Get in touch with Trimble, Inc., and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

![3月21日-封面[1].jpg](https://cdn.geo-matching.com/voeE1ywo.jpg?w=320&s=6b3b1a0215d770f8797653e9202a8f52)