Utility Upgrades Field Workflow To Meet New Regulatory Requirements

With ArcGIS Utility Network and ArcGIS Collector, AltaGas Utilities Reduces Inspection Times by 50 Percent. In 2015, leaders in the natural gas industry in the United States published a collaborative document called ASTM F2897 that specifies how pipeline attributes, including the materials they’re made of and their manufacturers, should be identified via a standard, 16-digit bar code.

AltaGas Utilities Reduces Inspection Times by 50 Percent

In 2015, leaders in the natural gas industry in the United States published a collaborative document called ASTM F2897 that specifies how pipeline attributes, including the materials they’re made of and their manufacturers, should be identified via a standard, 16-digit bar code.

Bar code capture improves how quickly field staff collect data and reduces the amount of information they have to gather manually.

“ASTM F2897 is the standard that the gas utility industry is rallying around to address the requirements of tracking and traceability,” said Tom Coolidge, Esri director of gas utility and pipeline industry solutions, referring to the need to find where assets were installed (tracking) and locate them based on attributes (traceability).

Being in compliance with ASTM F2897 requires that utilities have a barcode-based method to collect and store this data.

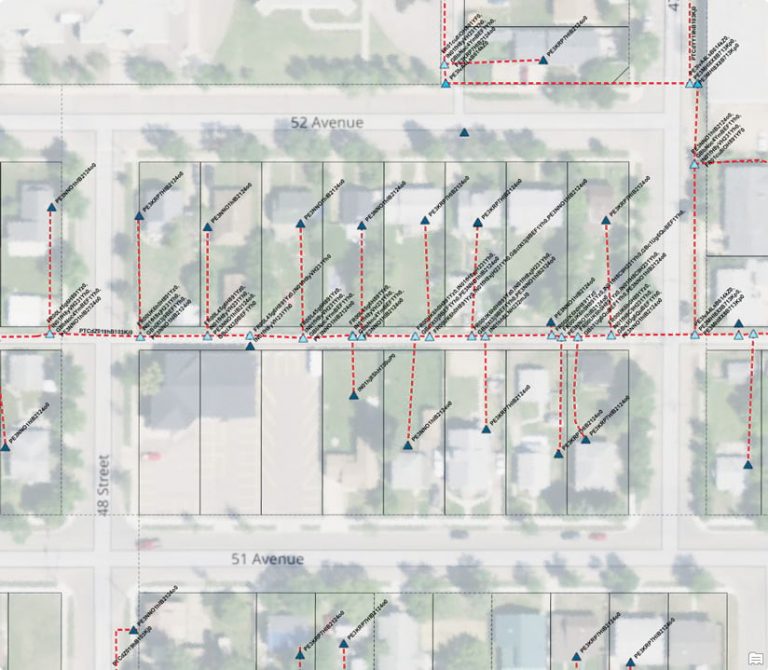

AltaGas Utilities, a regulated Canadian natural gas distribution utility with more than 13,000 miles (21,000 kilometres) of pipeline, has spent the last several years putting plans in place to comply with this standard proactively. Its GIS team has spent three years updating the utility’s digital as-building process (which involves collecting location and other information about newly installed assets before they are backfilled underground) so it works with bar code scanning.

“Our intention is for a bar code to be scanned on all polyethene [PE] assets during installation,” explained AltaGas Utilities GIS manager Mathew Desbiens. “Then we can go back and trace exactly where those underground assets are by using our GIS.”

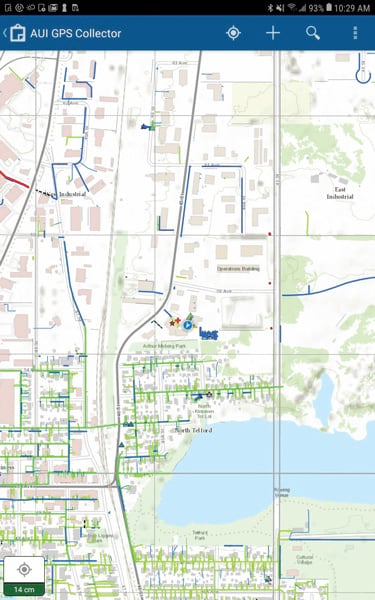

To do all this, AltaGas implemented the new ArcGIS Utility Network extension and ArcGIS Collector, along with the Arrow Gold Global Navigation Satellite System (GNSS) receiver from Esri partner Eos Positioning Systems and rugged tablets from Samsung. Now, the utility has everything it needs to comply with ASTM F2897.

Durable Technology

For three years, AltaGas worked closely with Esri and Esri Canada to update its GIS. This included participating in the Utility Network beta program. Esri has enhanced the Utility Network extension and Collector to streamline ASTM F2897 compliance, which worked out great for AltaGas. “We wanted to move to the Utility Network for our GIS because Esri made it directly compatible with the ASTM F2897,” said Desbiens. “There is already a field with associated domains for every required attribute to go into Esri’s Utility Network schema.”

Moreover, Collector now has ArcGIS Arcade scripting, which makes it possible to display decoded bar code data in the field, even in disconnected areas.“The recent improvements to Collector can result in a simpler and more efficient tracking and traceability workflow when combined with an ArcGIS 10.7 or higher enterprise geodatabase,” said Tom DeWitte, Esri’s natural gas industry technical lead.

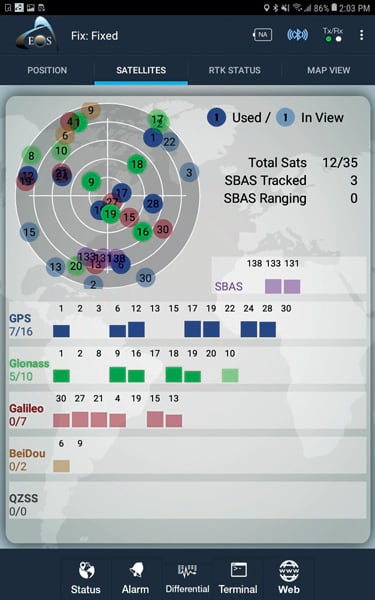

To make Collector work for the utility’s needs, Desbiens looked for a GPS receiver that was compatible with Collector to replace its legacy, all-in-one GPS data collection devices. The Arrow Gold GNSS receiver provides centimetre-level accuracy with real-time kinematic (RTK) corrections or submeter accuracy via free, satellite-based augmentation system (SBAS) wide-area augmentation system (WAAS) corrections. This is what Desbiens was looking for, along with devices that could stand up to Canada’s often harsh environment.

“Two of the other receivers we tested could not withstand the harsh Alberta climate,” Desbiens said. “Now we’ve got 22 Arrow Gold receivers out there, and they’ve been working flawlessly. And the Eos technical support we required for interfacing with Collector was outstanding.”

By using a paid RTK subscription in urban areas, AltaGas achieves several centimetres of accuracy. In rural areas without RTK, the utility achieves below 1 meter. “We like to have 30-centimetre accuracy or better in most cases,” said Desbiens. “And below 1 meter is more than adequate for us in rural areas.”

Desbiens Bluetooth-paired the Arrow Gold GNSS receivers with Samsung Galaxy Tab Active 2 tablets loaded with Collector. These tablets tested best among mobile devices.

“They avoided the Bluetooth connectivity issues we had with other devices,” said Desbiens. “And the installation and operation of Collector were seamless.”

Saving Time for Inspectors and Drafters

AltaGas Utilities rolled out the new field data collection system to 50 contractors and employees. In the past, only internal employees were able to do the company’s as-building work because legacy devices didn’t allow fieldworkers to sync their data to a server in the cloud. “You had to work for the company, AltaGas Utilities, to access any of the data,” said Desbiens.

Now, independent inspectors, who already visit installation sites to provide safety oversight and inspect assets before they’re powered up, can also collect data on as-built assets. “Just by scanning a bar code and getting rid of [drop-down menus], we’re saving 50 per cent of our field time for inspectors,” said Desbiens. “This made our business case very clear.”

Once the data is collected, drafters back in the office use a custom geoprocessing tool in ArcGIS Pro to decode the collected bar codes and add them to AltaGas’s tracking-and-traceability attributes, which are based on tables in the ASTM F2897 document. “Collector will automatically decode the bar code, auto-populate the derived attributes, and display the decoded information immediately after the new GIS feature is submitted by Collector,” said Doug Morgenthaler, Esri’s program manager for Collector.

AltaGas Utilities created a custom JavaScript geoprocessing tool in ArcGIS Pro to perform bar code translations. The company also enabled a capability that groups together multiple bar codes as one feature. “Our inspectors can save a lot of time because they can scan, scan, scan, and submit a single feature,” said Desbiens.

“Our inspectors can save a lot of time because they can scan, scan, scan, and submit a single feature”

While AltaGas built its workflows, Esri Canada director of utilities Brian Bell acted as an adviser to ensure that everything collected in the field was supported back in the office GIS.

“My team helped them build their knowledge to make the right decisions,” said Bell. “In return, they gave our product teams crucial feedback as to where they needed to focus to deliver a solution for their business challenge.”

Wider Use in the Future

Under the guidance of Desbiens, AltaGas Utilities is currently assisting in the development of similar workflows at its sister utility Pacific Northern Gas. AltaGas has also purchased its own Arrow Gold base station, which will eliminate its need for third-party RTK network subscriptions and save the utility $1,500 per year, per user.

“Not only will adding the base station eliminates their subscription costs,” said Bernard-Luc Gagnon, an authorized Eos representative who installed the Arrow Gold base station, “but now they will have more people in the field who can benefit from survey-grade accuracy.” The base station provides 1–3 centimetres of accuracy within a 30-mile (50 kilometres) radius.

“This will cover a considerable amount of our urban areas,” said Desbiens. “We feel very positive about the business case we presented, the results we have been able to achieve, and our preparation for potential upcoming regulatory requirements.” Meanwhile, the utility’s three-year pilot program has helped Esri ensure that its enhancements to the Utility Network and Collector have meaningful value for other gas operators facing upcoming regulations.

“AltaGas Utilities was an early adopter,” said Esri global director of utility industry solutions Matt Piper. “My expectation is that virtually every gas utility will find its way toward using these kinds of capabilities.”

Do you have questions about this case study?

Get in touch with Eos Positioning Systems, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

Related products

![3月21日-封面[1].jpg](https://cdn.geo-matching.com/voeE1ywo.jpg?w=320&s=6b3b1a0215d770f8797653e9202a8f52)