Dyneema & Kevlar Rope

High Strength,High Modulus,Low Density,Widly Application Kevlar Rope; Ultra-High Strength, Lower Elongation, Double Braided Dyneema Rope

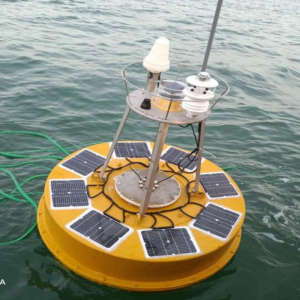

The physical properties of high-strength and high-modulus polyethylene fibers are excellent. Mainly used on plankton trawl nets, it can provide static buoyancy, and the load-bearing capacity is lower than that of Kevlar ropes.

Description

Dyneema Rope

Due to its high crystallinity, it is a chemical group that is not easy to react with chemical agents. Therefore, it is resistant to water, humidity, chemical corrosion, and ultraviolet rays, so there is no need to undergo ultraviolet resistance treatment. Corrosion resistance, acid and alkali resistance, excellent abrasion resistance, not only has high modulus, but also soft, has a long flexural life, the melting point of high-strength high-modulus polyethylene fiber is between 144~152C, exposed to 110C environment for a short time will not cause serious performance degradation, etc.

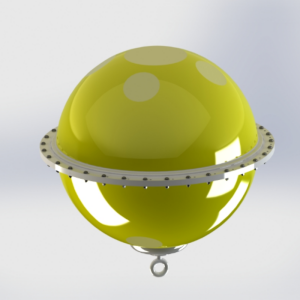

Kevlar rope

The Kevlar rope used for mooring is a kind of composite rope, which is braided from arrayan core material with low helix angle, and the outer layer is tightly braided by extremely fine polyamide fiber, which has high abrasion resistance, to obtain the greatest strength-to-weight ratio.

The low helix angle braiding technology minimizes the downhole breaking elongation of the Kevlar rope. The combination of the pre-tightening technology and the corrosion-resistant two-color marking technology makes the installation of downhole instruments more convenient and accurate.

The special weaving and reinforcement technology of the Kevlar rope keeps the rope from falling off or fraying, even in harsh sea conditions.

Do you have questions about this product?

- Questions about price, availability, and/or retailers

- Questions about technical specifications and usage

- Questions about suitability for your project or application

Specifications

-

Physical Properties

-

UV resistance

-

General

-

Typical applications

Ocean monitoring

Documents