TG63

3D Grade Control System.

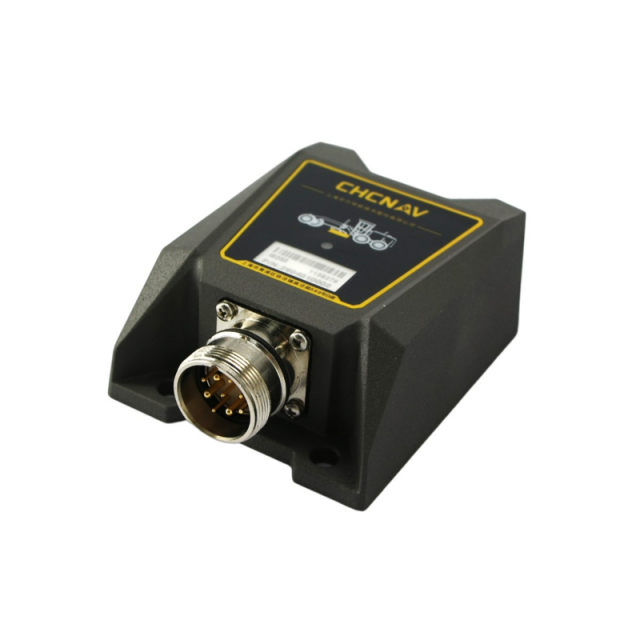

High-accuracy 3D automatic grade control solution for motor graders with the dual-GNSS+INS positioning system.

Description

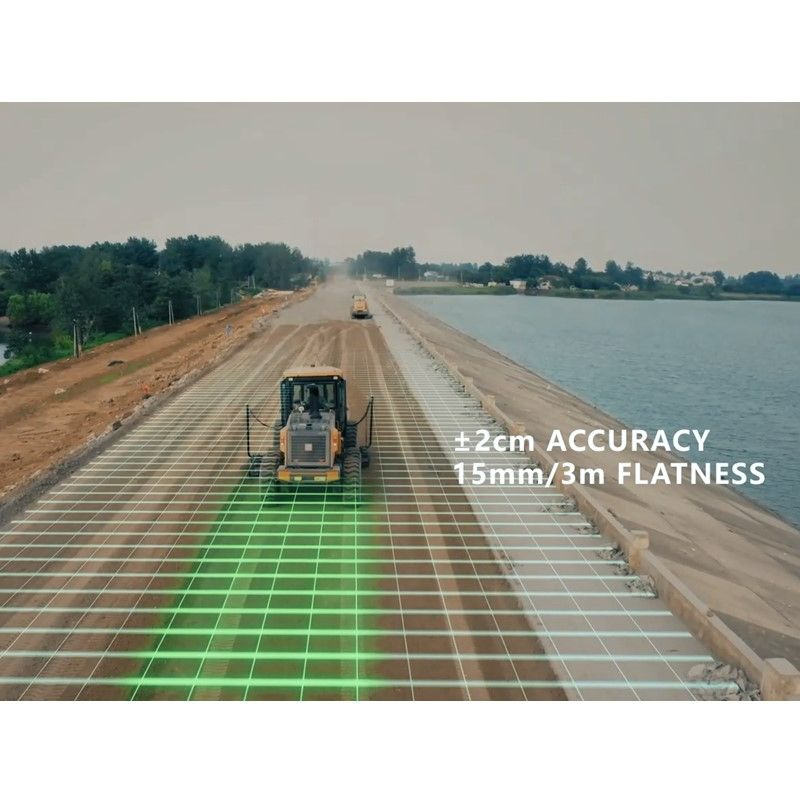

- +/- 2 CM GRADING ACCURACY

High-dynamic positioning with Dual GNSS+INS.

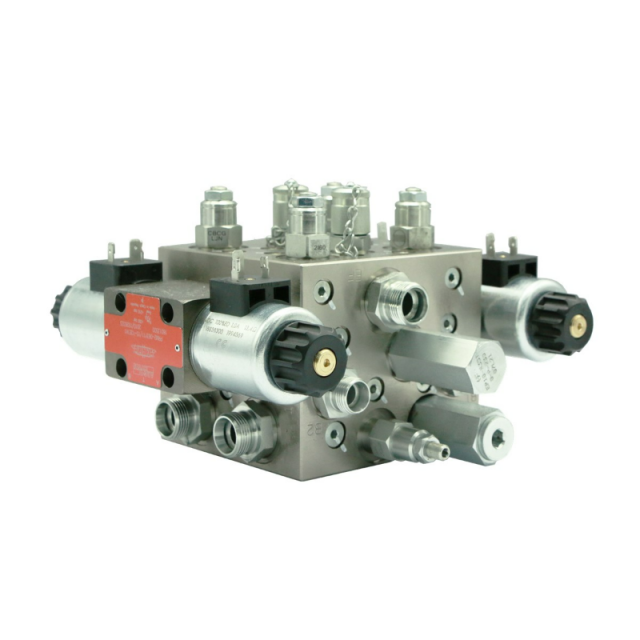

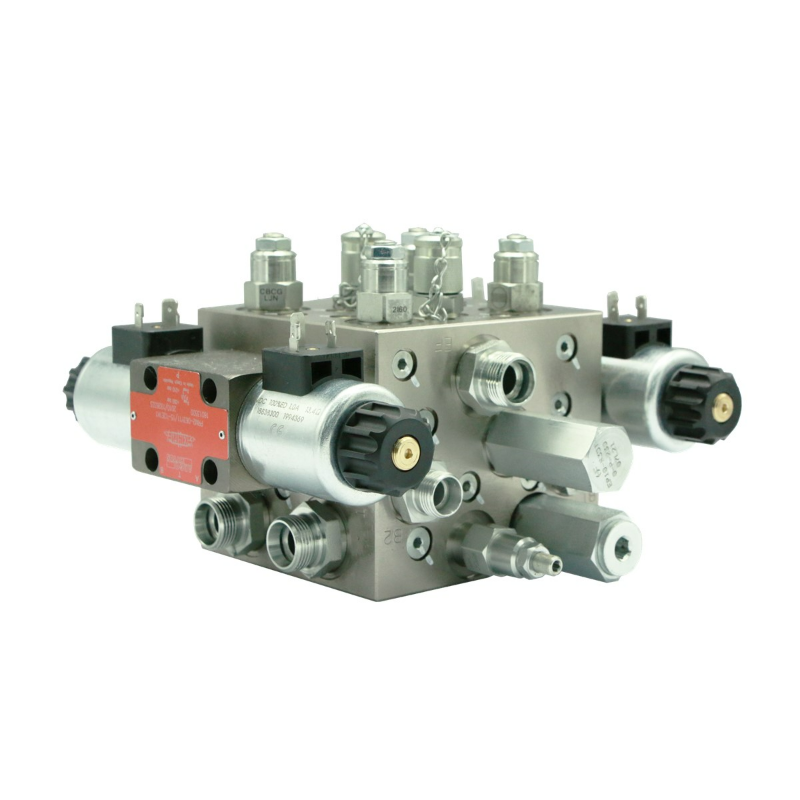

The CHCNAV's GR-Tech technology combines dual GNSS satellite positioning with inertial navigation to ensure ultimate accuracy in driving the grader blade to within ±2 cm, regardless of the machine's position. The multi-band GNSS sensor supports multiple correction sources, including RTK NTRIP and UHF base station, to match your operating conditions. In addition, the high-response valve module, with multiple pressure relief plugs, adjusts the blade position to maintain the efficiency of grading; this ensures that the fine-grade accuracy requirements of earthmoving operations are met at all times, and only the correct quantity of soil or other material is moved.

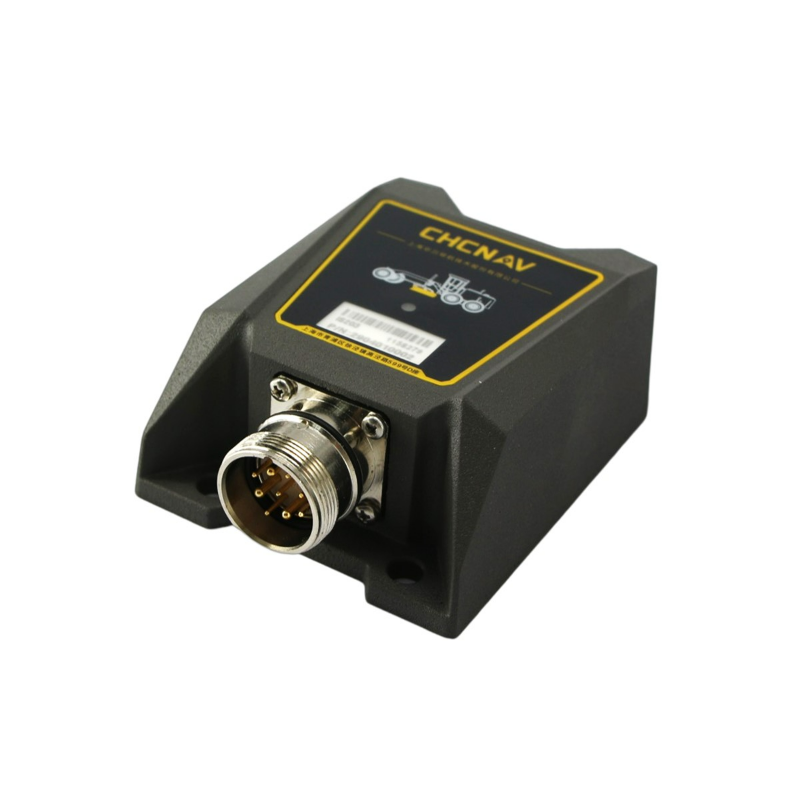

- ROBUST DESIGN AND PROVEN RELIABILITY

Extended durability in construction environments.

The TG63's industrial design is built to withstand the harsh environment expected on construction sites. Dust and waterproof components, rugged anti-glare touchscreen, and durable, high-response valve module ensure fast, reliable work all year round. More than just robust and rugged GNSS technology, the TG63 grade control system helps our clients complete their projects on the most difficult sites with fewer machines by bringing significant gains in productivity, accuracy, and speed to earthmoving applications, whether it's used in civil construction, roadworks or on remote mining sites, consequently, bringing a faster return on investment.

- FAST & EASY-TO-USE SOFTWARE

Intuitive GradeNav software for a quick learning curve.

The GradeNav software runs on a 10.1" industrial color display for optimal readability in job site environments. It supports standard AutoCAD DXF design files, including surfaces, slopes, TINs, and road features, to manage all common grading operations effectively. The intuitive GradeNav software enhances the experience of machine operators, even those with little to no experience, in every way possible to complete projects quickly and accurately. Several user-defined configurations can be set up to determine the working parameters of the site and make the operator's job simpler and easier.

- SAFE OPERATION IN ALL SITUATIONS

Full control is always at the hands.

Because safety on the job site is critical, operators can quickly engage and disengage the automatic blade control mode by using the switches provided and mounted next to the outermost control handles in the cabin. In addition, the manual override mode allows operators to take control of the blade directly in an emergency case.

The CHCNAV TG63 is an automatic 3D grade control system for motor graders designed to improve the quality and efficiency of grading operations. The high-precision dual-GNSS positioning system and inertial sensor featuring the GR-Tech technology provide reliable 3D positioning and heading to control the motor grader blade, regardless of the machine's position and site conditions. Real-time automatic control of the blade to design the surface allows finished grading accuracy to be achieved in less time and increases efficiency and productivity by eliminating the need for manual staking.

The 10.1-inch industrial touch screen keeps the system operating at the operator's fingertips. The GradeNav software provides complete and user-friendly control to the machine operator. Detailed displays of job information, including project configuration, cut and fill data, and geofencing areas, are always accessible at a glance. For added safety, an optional rear camera is available to provide the operator with an even broader view of the job site.

By breaking the price barrier, the TG 63 provides construction companies of any size with a complete, integrated solution for grading operations that allows the work to be done faster, delivering better results with overall data consistency and less rework.

Do you have questions about this product?

- Questions about price, availability, and/or retailers

- Questions about technical specifications and usage

- Questions about suitability for your project or application

Specifications

-

General

-

Year of introduction

2022

Main design elements

hardware and software

Field of Use

3D grade control system for motor graders designed to improve the quality and efficiency of grading operations in civil construction, roadworks or on remote mining sites

-

Operation Characteristics

-

Integrated sensors

-

Functionalities

-

View position, planned route and speed

Y

-

More information

-

Main applications

Grading operations

Distinguishable features

The high-precision dual-GNSS positioning system and inertial sensor featuring the GR-Tech technology provide reliable 3D positioning and heading to control the motor grader blade, regardless of the machine's position and site conditions.

-

Software

-

Versions

GradeNav software

Display of external data and photos

Y

Other Functionalities

It supports standard AutoCAD DXF design files, including surfaces, slopes, TINs, and road features, to manage all common grading operations effectively.

-

Display

-

Touchscreen

Display Panel

10.1" color touch screen; sunlight readable; IP66 dust- and waterproof; CAN Bus + RS232; GradeNav software; GR-Tech technology.

Documents