What is the Reason That Led ESTEIO To Own Leica ADS100 Airborne Digital Sensor

Despite 2020 being a period of great uncertainty caused by the ongoing global pandemic, Brazilian aerial survey firm ESTEIO Engenharia e Aerolevantamentos S.A has taken a leap of faith and invested in a large-format Leica Geosystems Airborne Digital Sensor ADS100, which represents the state-of-the-art technology in digital line-scan airborne imaging. With this purchase, ESTEIO continues to be an industry leader in South America by modernising and expanding its capabilities to meet its customers’ needs. The Hexagon team interviewed Valther Xavier Aguiar, Chief Technology Officer at ESTEIO, to gain insight into the company’s latest purchase.

To remain competitive in the aerial survey industry, companies have to keep up-to-date with rapid technological development. Throughout our 50 years in the market, ESTEIO has made huge investments in hardware and software focused on innovation, strategy, necessity, and opportunity. Despite usually being the shortest step in a mapping project, the image collection phase has the greatest impact on the costs and deadline of a contract due to its dependence on weather, time restrictions, and flight permits. Hence, it is crucial to have a reliable and high-performance aircraft and sensor ready for deployment.

Why did you decide to purchase an ADS100?

Upgrading our ADS40 to the ADS100 was a logical next step in our investment strategy. Our previous ADS40-SH52 sensor is Leica Geosystems’ second-generation digital line sensor, whereas the ADS100 is the fifth-generation sensor. All technology advancements of the past few years have been integrated into the ADS100.

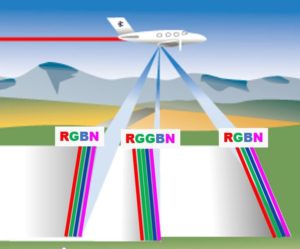

The power consumption was minimised, and the system weight was significantly reduced from 230 kilograms (kg) to 120 kg. Other benefits include a gyro-stabilised mount, high-performance inertial system, a unique telecentric lens with interference filters, red, green, blue and near-infrared spectral bands individualised in all three views, 20,000-pixel nadir images across track, and more.

These improvements lead to a longer range, augmented memory capacity, and increased recording speed, allowing us to acquire data faster and in low light conditions and increase our productivity by up to 70%. The higher resolution enables us to obtain images with GSD (ground sampling distance) of as low as 3 cm, and the broader field of view allows for a larger swath width. Moreover, the novel TDI (Time Delay Integration) on a linear sensor avoids image smearing. When combined, all of these features result in a highly productive sensor with lower operational costs.

Did you also invest in new software?

Yes and no. For ESTEIO, one of the advantages of purchasing the Leica ADS100 sensor is that the processing workflow is the same as for the ADS40. We only had to update the workflow to a more recent and efficient version that can keep up with the increased data volume. By investing in the acquisition, which is the first phase of the mapping process, we also invest in the entire production chain. Every stage goes through small changes, and therefore, all technicians must attend training courses. Hence, the investment in hardware was also an investment in software and “peopleware”.

Why invest in a linear sensor and not in a full-frame sensor like most other Brazilian companies?

Firstly, because our previous large-format sensor was a linear sensor (also called a line-scanning or push-broom sensor), and we have always been satisfied with its quality and reliability. Secondly, and more importantly, linear technology has proven to be extremely efficient. In my opinion, it allows us to capture the best images from a geometric and radiometric point of view. It is the only multispectral imaging technology that does not use “pan-sharpening”. Images are captured directly in their native resolution in R, G, B and NIR spectral bands. When combining them, the final image does not display “ghosts” when capturing moving vehicles or colour duplication, which can occur with pan-sharpening.

Why has ESTEIO invested in the ADS100 and not in an oblique sensor?

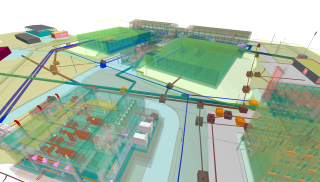

Oblique imaging, along with 3D modelling, shows excellent market potential. However, it is still too expensive for most of our clients and the Brazilian local governments, and few are prepared to handle the large amount of information produced by oblique systems. During a pilot project in 2016, ESTEIO explored the technology and showcased its capabilities by completing the first oblique mapping project in the country.

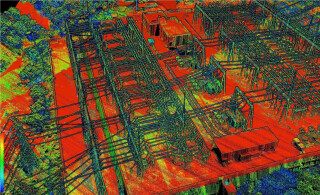

By mastering the oblique imaging technology, we are prepared to meet the demand for 3D city models in the future. When we invested in the ADS100, we also purchased almost all peripherals and software necessary to operate an oblique sensor. When the time comes, acquiring an additional sensor head will allow us to manage oblique imaging or LiDAR projects. We are keeping an eye on the Leica CityMapper-2 since it includes oblique imaging and LiDAR sensors. As such, we could invest in oblique mapping capability with our next LiDAR sensor upgrade.

Most Brazilian aerial survey companies have medium-format sensors. Why has ESTEIO decided to invest in a large-format sensor?

ESTEIO’s primary concern is to cater to our clients’ demands, who ultimately are the reason why the company exists. ESTEIO already owns medium-format sensors used alongside LiDAR for point cloud colourisation. The ADS100, however, plays in a league of its own. With the acquisition of the ADS100, ESTEIO aims to keep its leadership in the market and remain up-to-date in mapping technology.

A medium-format frame sensor may not always meet the clients’ needs and specifications, especially if they require multispectral images in distinct R, G, B and NIR bands, images without smearing, the use of a stabilising mount, etc. With the ADS100, the 1:1 relationship of all four colour bands is ideal for remote sensing applications.

In case both sensors (ADS100 and medium-format) can fulfil the demand, ESTEIO will recommend the more cost-effective solution. Depending on project specifications, the size of the survey area, location, weather conditions, product requirements, etc., the project cost can very well be lower with the ADS100 because the line-sensor is much more efficient. The ADS100 requires less time for data acquisition which reduces overall project cost. Our clients who are familiar with both technologies usually hope that their project will be completed with the line-scanning sensor.

Why has ESTEIO invested heavily in a large-format digital airborne sensor after drones have become so popular?

Drones are valuable new instruments in the aerial imaging market, but most of them do not meet high-precision mapping requirements. And when they do, they are only suited to survey very small areas due to their limited range. ESTEIO has invested in an advanced, high-productivity sensor, which by no means resembles the small cameras installed in most drones – it’s almost like comparing a bicycle to a Mercedes-Benz.

Both “sensors” may take beautiful aerial images, but there are significant differences in geometric and radiometric quality, and especially in efficiency. Many countries have been mapped with the ADS100 sensor due to its high productivity, quality, and reliability. The ADS100 sensor allows us to obtain images with individual spectral bands and multiple stereoscopic views and generate products with a suitable geometry for technical services that demand high quality and information integrity. Precision mapping over extended areas is not yet a suitable application for drones.

Drones, aircraft or even satellites are merely the vehicles that transport the sensors, which actually determine the quality of the survey. Today, it is financially impossible to operate a 120-kg sensor with a drone because unmanned vehicles with high load capacity are still too expensive and less safe compared to manned aerial vehicles. The sensors that feature state-of-the-art technologies are heavy and depend on too much power to be operated with drones. In the future, if these sensors are miniaturised, or when larger drones with bigger payloads become common and face fewer operational restrictions, a replacement may be feasible. Should this development become a reality, we look forward to being at the forefront of drone mapping!

Valther Xavier Aguiar, Chief Technology Officer at ESTEIO Engenharia e Aerolevantamentos S.A

Brazil, was interviewed by Viviana Fuso, Marketing Communications Director at Hexagon’s Geosystems Division, Switzerland.

Do you have questions about this case study?

Get in touch with Leica Geosystems Airborne Solutions, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.