Using a UAV for the Analysis of Transmission Lines

Keeping in line with its commitment to evolving technology, Missouri-based Anderson Engineering committed to drone technology earlier than most, purchasing their first vehicle about 3½ years ago. According to AE vice president Jerrod Hogan, while the “hobby drone,” as he calls it, showed them what was possible, it also spotlighted all the shortcomings of the technology as it existed then.

“We have always been about bringing new technology to bear to provide better service to our clients; it just made sense to go in that direction,” he said. “Even though our first unit was very basic by today’s standards, we felt that, even if it did just a few things, we could probably break even — if it did all that we hoped it would, we could make money. We tried it on several photogrammetry and power line/tower inspection projects and, while it was moderately successful, the efforts spotlighted the technology’s limitations, including short battery life, problems with stability, and limitations due to wind conditions.”

In addition, the unit’s GoPro camera, while impressive for other tasks, couldn’t give them the accuracies they needed. To do inspections, they had to fly extremely close to their target and that drone didn’t have the necessary stability for such proximity. Nevertheless, it let them know they were on the right track.

"... if we were hovering 20 feet off a power line and the wind suddenly blew the aircraft in the direction of those lines, the Falcon 8 would instantly correct itself and stay in position." - Anderson Engineering Vice President, Jerrod Hogan

Timely Delay

Some unforeseen delays gave AE the time to explore other options available to them. Extensive research pointed to the Topcon Falcon 8, powered by Intel®, an eight-blade rotary-wing UAV that offers first-in-class sensors, active vibration damping, and compensating camera mounts for solid performance — all features which fit perfectly with AE’s needs. Working with Chad Willey, currently, the sales representative and UAV specialist at Springfield-based Topcon dealer Ozark Laser & Shoring, the firm arranged for a demo session. According to Hogan, Willey did the demo and the performance changed the way the engineering firm looked at UAVs. He said that the eight blades offered stability they never had before, battery life was greatly improved and problems dealing with changing wind conditions became, to a large degree, a non-issue.

“Chad showed us that, if we were hovering 20 feet off a power line and the wind suddenly blew the aircraft in the direction of those lines, the Falcon 8 would instantly correct itself and stay in position. That ultra-stable platform, coupled with the images it was able to produce, sold us on the spot.”

In the Details

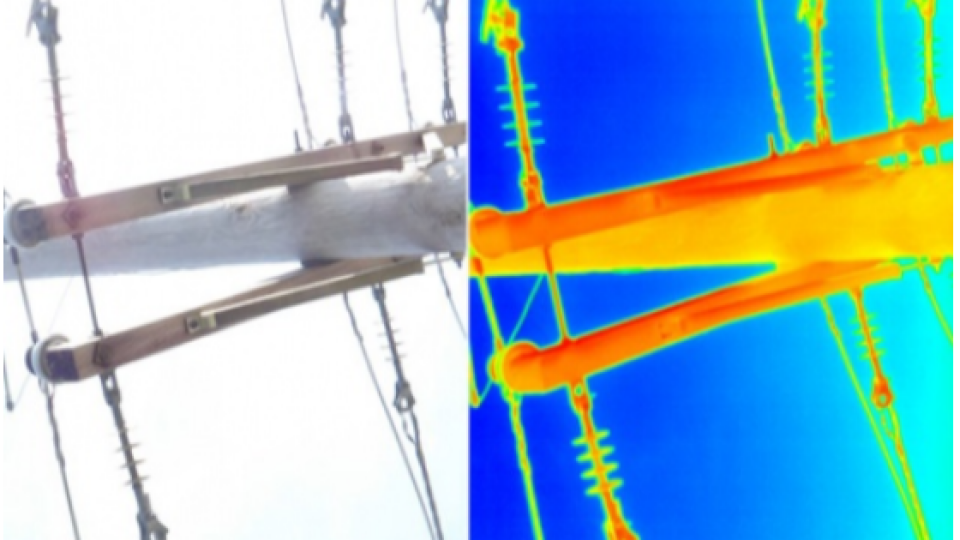

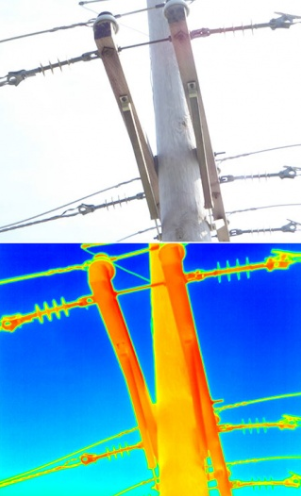

The firm purchased the UAV with two separate camera packages. One, used for inspection, features a 12 megapixel Panasonic Lumix DMC-TZ71 with 30x optical zoom and FLIR Tau 2 IR camera which has allowed the company to augment traditional power line inspections with an infrared capability. This combination collects both thermal and RGB images simultaneously, allowing the user to get detailed actionable information on an asset’s condition.

“Overall, the power line inspection effort has been streamlined and made safer with the UAV. To inspect those traditionally, a worker is either attached to a helicopter platform or on the ground in a bucket truck. It is a labour-intensive and often risky process. Time-wise, our UAV can beat a manual inspection by a rate of about 5:1 — and the safety factor is exponentially higher as well.”

The other package AE chose includes a 36 MP Sony Alpha 7R DSLR camera which provides ultra-high resolution images — invaluable in both inspection and photogrammetry applications. Hogan said he was immediately blown away by just how powerful the zoom feature was.

“With the Topcon Falcon 8 purchase, we went from doing a decent job at a distance with our old drone to being able to say with confidence to the client: ‘This cotter pin is broken, or that bolt needs three turns.’ It was a game-changer, for sure.”

"I lowered the drone down, rotated it, got the images we needed and brought it back up." - Jerrod Hogan

Huge Improvement

Though inspections still make up a good portion of the AE workload, Hogan says conducting topo surveys using the vehicle has become commonplace for them.

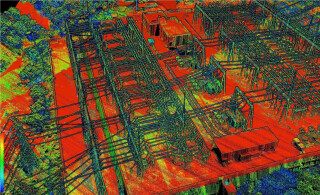

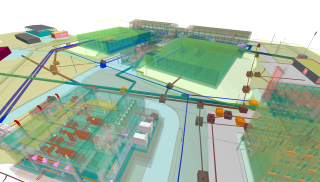

“We recently teamed up with another engineering firm to do some flood plain modelling for the city of Cassville, Missouri to help them be better informed with regard to future development and better equipped to predict how flooding will impact their community. We first went out and set up ground targets to establish good control, flew the project with overlap, and brought all that data into Pix 4D, our mapping software. From there, we created the 3D model to accompany the orthophoto of the project area. The results were impressive and, most importantly, the client was very pleased.”

Hogan added that preparation for any UAV flight is made far simpler through the use of AscTec Navigator flight planning software. Their previous drone took a picture every two seconds, forcing them to have to set the focal distance on the camera, consider the field of view, altitude, etc., then go back to the map and begin calculations.

“We basically had to draw the whole flight plan out by hand,” he said. “With the Topcon solution, once we draw all the necessary boundaries around the job, we tell it what kind of overlap we want — both front and back, as well as side to side — tell it the degree of accuracy we need, and it sets our flight altitude above ground. It calculates the full flight plan, tells the drone to fly to a particular location and, using lines and pre-determined waypoints, gathering data at each waypoint begins. It’s an amazing solution.”

Going Down

One of the obvious benefits of a UAV to a company like Anderson Engineering is its ability to perform tasks in situations that are considered risky for workers. On a sinkhole project in nearby Springfield, that benefit played out in a huge way. According to Hogan, when previously faced with sinkhole projects, AE’s Geotech and structural engineering divisions would work together to try to assess why the sinkhole occurred and what structural solution might be needed to ensure it doesn’t occur at that location again.

Part of that evaluation process often involved lowering a man into the sinkhole to take photos of the surrounding environment — effective, but an obvious safety risk.

“However, armed with the Falcon 8, it became an entirely different approach,” said Hogan. “We first flew a top-down view to get the whole project georeferenced with our ground targets and to get a good view of the hole itself. Then, we slowly descended into the hole to gather our oblique images. The platform was unbelievably stable. I lowered the drone down, rotated it, got the images we needed and brought it back up. Then we used Pix4D to generate a highly-accurate, georeferenced model. The results were far more accurate than before, any worker was removed from harm’s way and the client was better served.”

Forward Thinking

To say that the UAV has ingrained itself into Anderson Engineering’s workflow would be a gross understatement. Hogan said that the aircraft had been in such demand that it recently became obvious a second UAV was needed. He was told by both offices that, if they bought something else, they would still be fighting over the Topcon unit.

“It’s safe to say that the first Falcon 8 paid for itself in about a year — and it’s tough to argue with a one-year ROI,” he said. “In light of that, we purchased a second Falcon 8 and both aircraft are currently kept busy on a daily basis.

Do you have questions about this case study?

Get in touch with Topcon, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.