Quay Wall Inspection With NORBIT Multibeam Echosounders

This case study highlights the benefits of using the NORBIT WINGHEAD i77h sonar for quay wall and vertical structure inspections in ports and harbours.

The NORBIT WINGHEAD is a very compact ultra-high resolution multibeam survey system with the following key features.

- Frequency agile 200-700kHz.

- 0.5 x 0.9°beam widths at 400kHz

- HD beamformer providing 1024 beams per ping

- High performance integrated GNSS/INS systems

- Integrated sound velocity and temperature sensor

- Small form factor and low power consumption

- Designed for rapid mobilization on any platform

- Options available with full motion stabilization (roll, pitch & yaw)

- Available with optional LiDAR.

Small Form Factor

All components fit in a single pelican case that meets airline baggage requirements:

– NORBIT WINGHEAD® i77h sonar with integrated IMU

– GNSS antennas

– Topside unit

– Sonar and antenna cables

– Optional sound velocity profiler

– Optional LiDAR

Image 1: All components of the NORBIT WINGHEAD

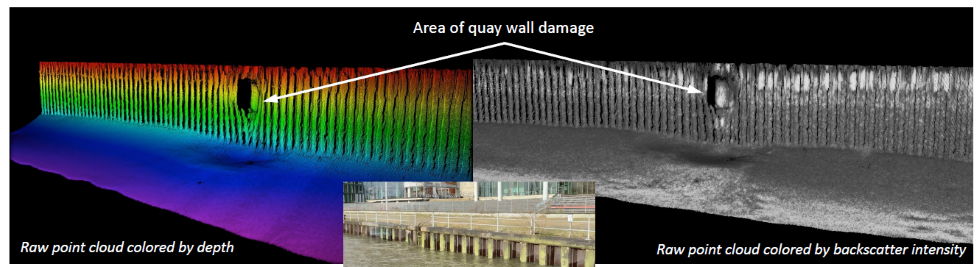

Detecting Quay Wall Damage

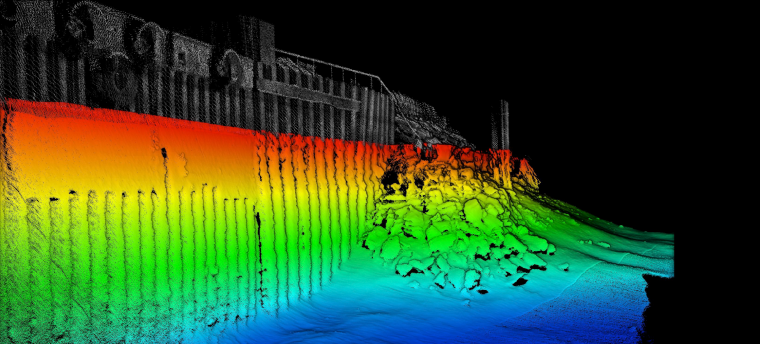

NORBIT’s curved array technology allows beams to be steered electronically without physically rotating the sonar.

– With conventional multibeam systems, beam width resolution degrades significantly as the beam

steering angle increases away from nadir.

– With curved arrays, beam spreading is significantly less, which makes the NORBIT WINGHEAD ideal

for quay wall inspection work where high resolution is required.

Image 2: Inspection of a quay wall

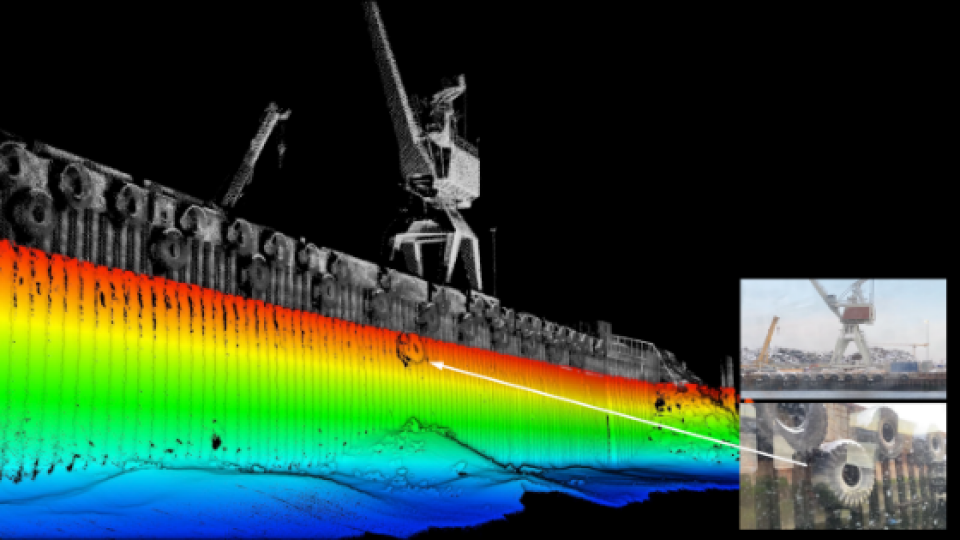

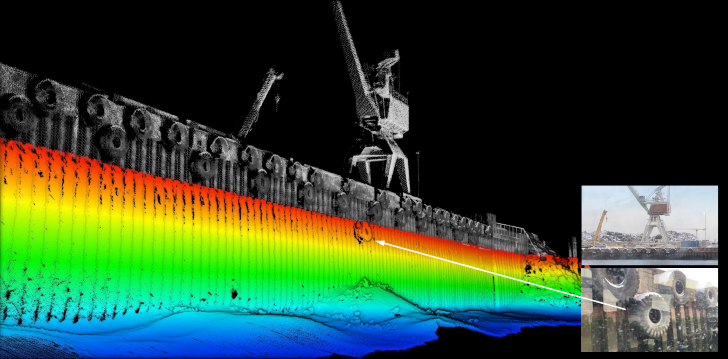

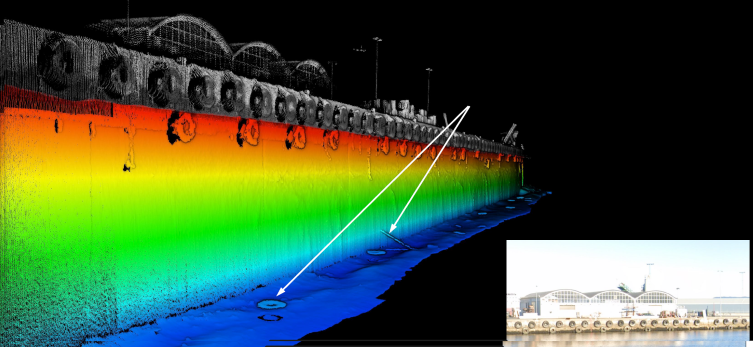

Combined Multibeam and Lidar Data

The multibeam can be combined with the optional NORBIT iLiDAR to obtain a full picture of the infrastructure above and below the waterline. This provides context for the multibeam data and aids interpretation of the results.

Image 3: Full picture of infrastructure above and below waterline

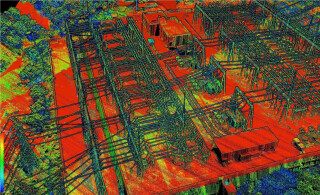

High Resolution

The NORBIT WINGHEAD generates up to 1024 true beams per ping, providing ultra high sounding density on the quay wall, which is essential for reliable inspection work.

Image 4: Point cloud of quay wall inspection

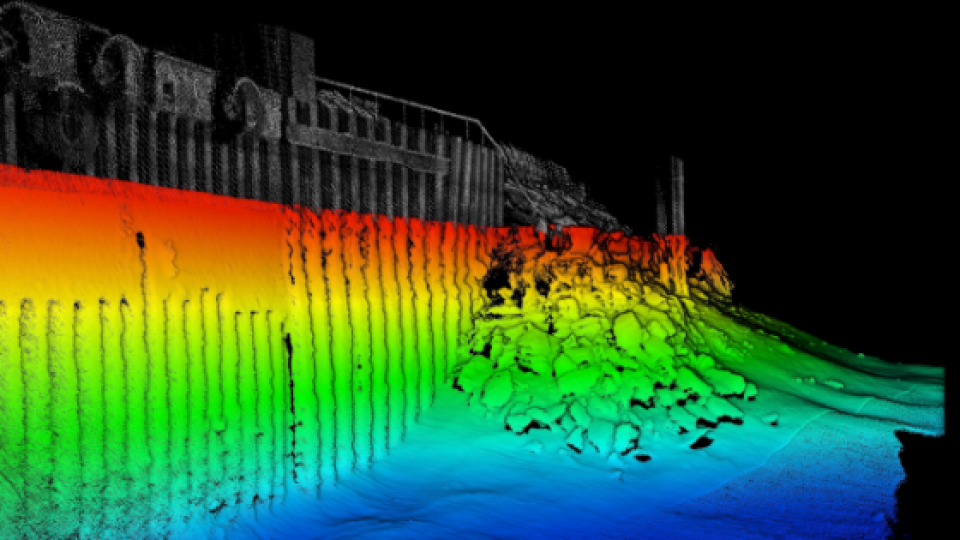

Feature Detection

Rocks which have fallen from the quay side into the water are detected in both the Lidar and multibeam data.

The WINGHEAD offers 0.5x0.9°beams at 400kHz, providing extremely high resolution data which enables tires and small objects, such as tree branches and ropes, to be detected.

Image 5: Identificating of small objects, such as trees and ropes

Do you have questions about this case study?

Get in touch with NORBIT Subsea, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

Related products