How USV Mounted Multibeam Echosounder Enhances Accuracy in Bridge Pier Scouring Survey

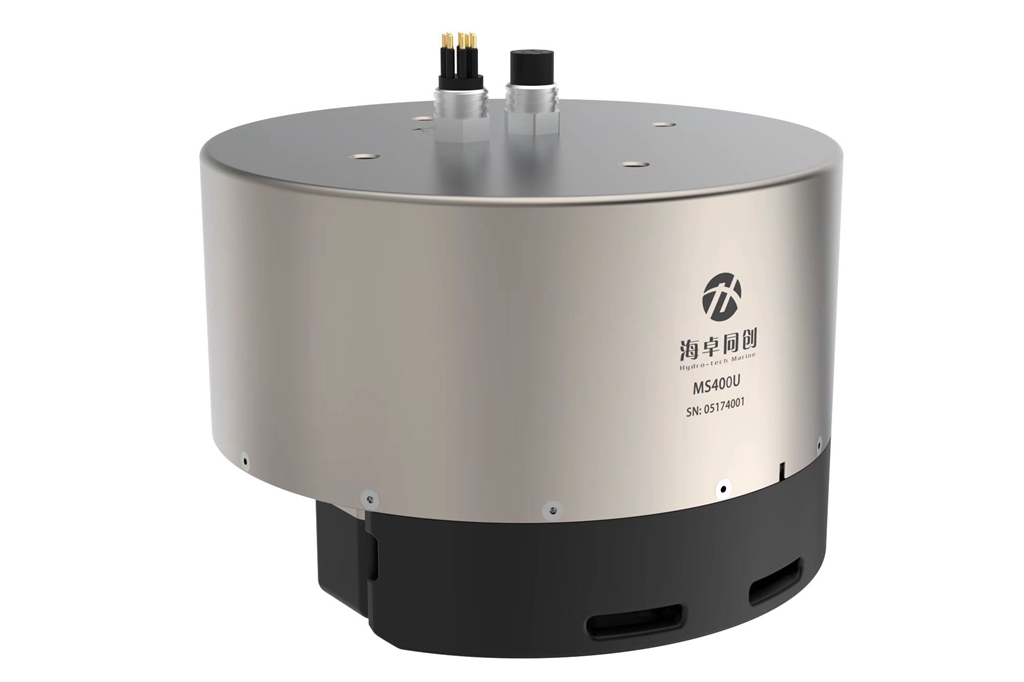

In order to improve the system integrating performance, MS400U has built-in many auxiliary survey sensors including sound velocity sensor, IMU and GNSS etc. User does not need pay more cost in purchase these devices in extra. Furthermore, this way also avoids installation error and enhance surveying accuracy. We are proud to say that we had truly achieve the goal of all in one! Through actual application of USV mounted with MS400U, it can greatly enhance the underwater surveying efficiency and safely. At the same time, the data accuracy of MS400U is very high, completely meeting the IHO standard.

Bridges are an important part of transportation, while bridge piers located in water are the cornerstone of traffic safety. If underwater environment has large tidal range, rapid flow velocity, serious sedimentation and scouring etc., all of these are invisible safety risks.

Built in 1973, Minjiang Bridge is located in a special geographical place where is in a big topographic drop from upstream and turbulent water flow and has caused scouring holes for a long time. This April, we undertake the important project of "Physical Examination" for Minjiang Bridge, which need high technology equipment to provide comprehensive data for security maintenance.

Traditional bridge scouring survey, also known as underwater topographic survey, often uses RTK GNSS receiver to collect data manually. This method has 2 shortcomings.

The operation is relatively dangerous, cause the flow rate near the pile foundation is big and the water flow is disorder.

The operation efficiency is very low, and the measuring accuracy may be difficult to meet the project requirements.

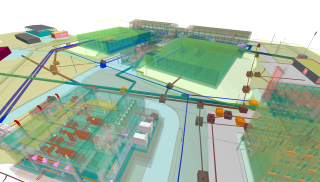

Therefore, this case will use Unmanned Surface Vessel integrated with Hydro-tech MS400U multibeam echo sounder. According to survey line designed base on survey area, MS400U will carry out moving measurement sounding underwater bridge pier to obtain high-precision underwater 3D data. This way efficiently solves the problems existing in traditional bridge pier scouring survey and can be significant referenced by all kinds of scouring monitoring work.

Project Solution

Comparing to single beam sonar, multi beam echo sounder’s working efficiency is greatly improved, and the water depth and underwater pile foundation terrain topography can be measured much higher precision.

Hydro-Tech MS400U consists of underwater parts and the other units on the deck. The underwater parts include transducer, which has receiving & projecting array, IMU sensor of SurfMaster, and sound velocity sensor of SVS1500. All of these parts are connected and communicated with deck unit (Or called Sonar Interface Module) through cables. The units on deck includes deck unit, which has built-in GNSS module, connecting with GNSS Antennas and main control computer running sonar display & control software and navigation & data acquisition software.

In order to improve the system integrating performance, MS400U has built-in many auxiliary survey sensors including sound velocity sensor, IMU and GNSS etc. User does not need pay more cost in purchase these devices in extra. Furthermore, this way also avoids installation error and enhance the surveying accuracy. We are proud to say that we had truly achieve the goal of all in one!

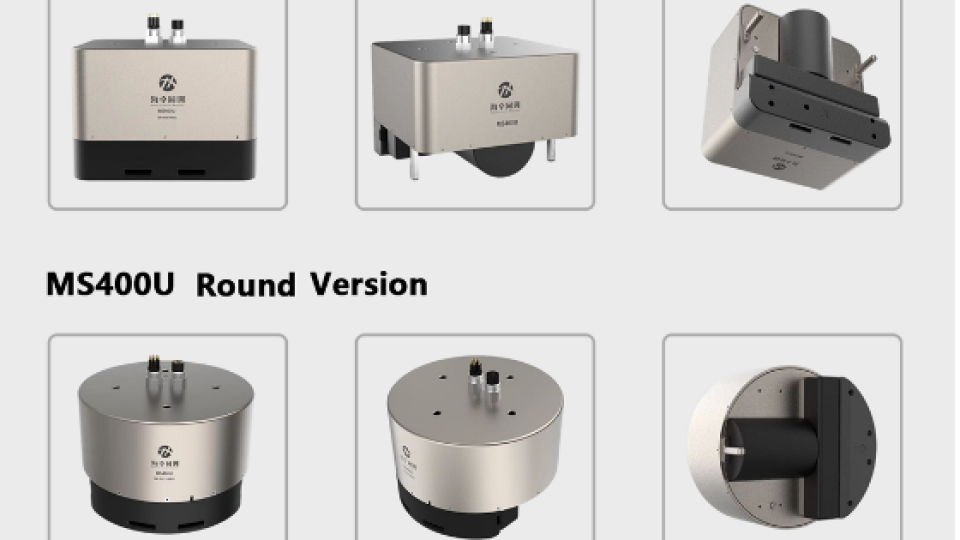

Conformal Design

In order to make the installation of Multibeam sonar more stable and reduce the error caused by vibration, we specially have the MBES and USV in conformal design, which can be installed directly and structure is very firm and solid.

At the same time, we have developed Round and Square ID Type in extra base on traditional MBES ID in T-type, so that our MS400U can better fit diversified types of USV.

MS400U Square version is suitable for the compact USV, which arrange each part in square order. While MS400U Round version better fit the small USV, which internal cabin is not enough. Then it can utilize the ADCP moon pool, dismantle the ADCP and install MS400U instead to collect the bathymetric data.

Project Operation

After installation of the multibeam echo sounder, sounding operation shall be carried out along the isobath. The display and control software and navigation acquisition software are used for sonar control and data acquisition.

During data acquisition process, the operator stands at the shore end connecting and controlling the operation of the unmanned ship through the network bridge and can visually view the equipment status and underwater operation. The MS400U has a built-in Inertial Navigation System. During operation, the positioning solution is always fixed and the communication with the shore end is always smooth. MS400U carries out underwater 3D scanning survey with 143° swath cector, directly measures underwater terrain within coverage and the 3D structure of the underwater pile foundation, and feedback the underwater terrain changes in the survey area.

Post Processing

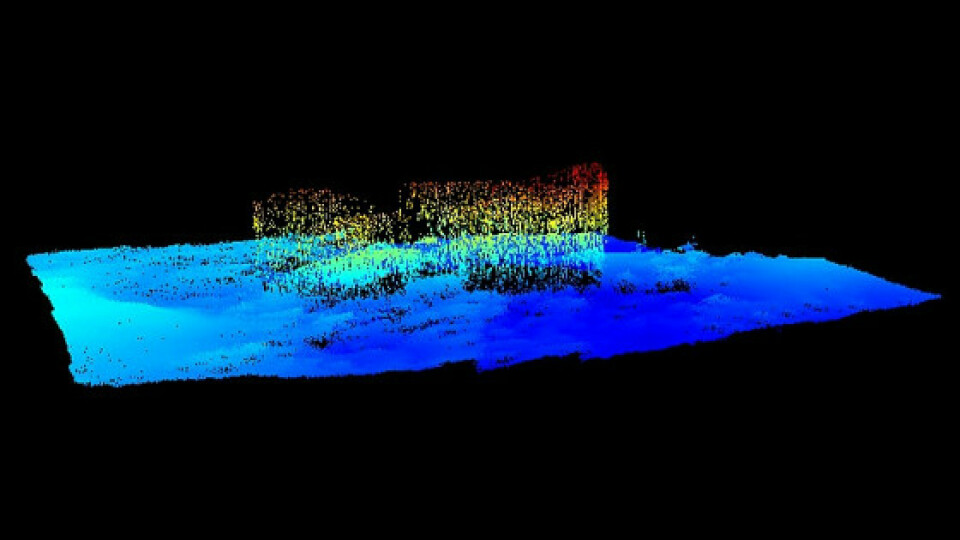

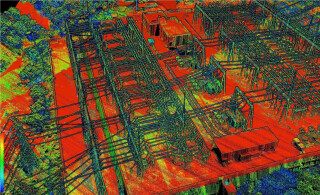

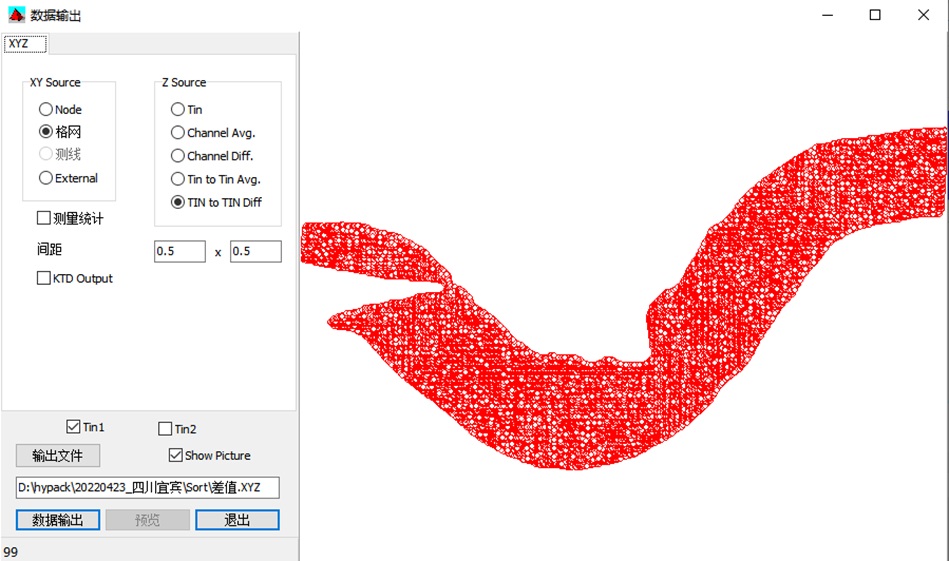

This project useHypack to do post-processing and output point cloud data of underwater pile foundation and terrain.

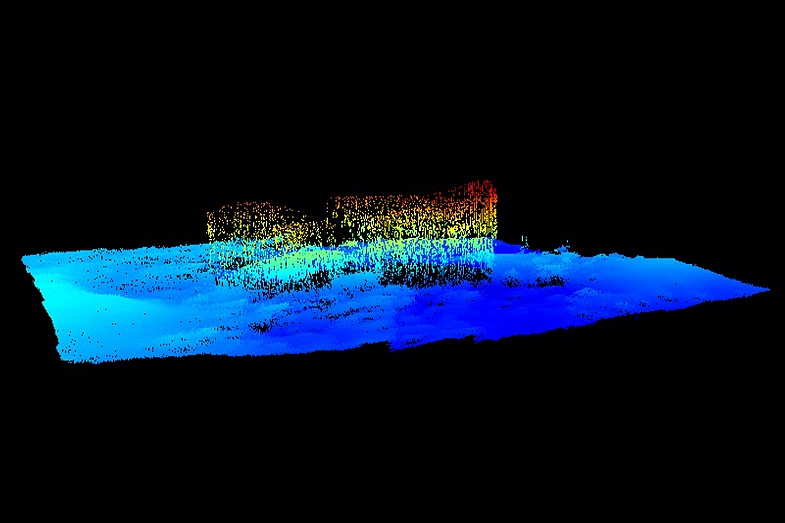

Then we can buildup a 3D model of underwater data through the TIN model.

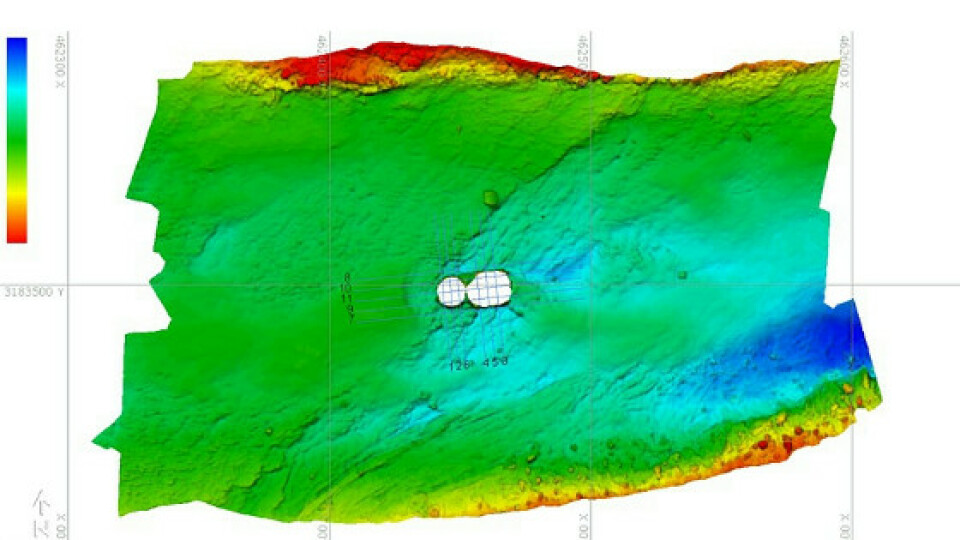

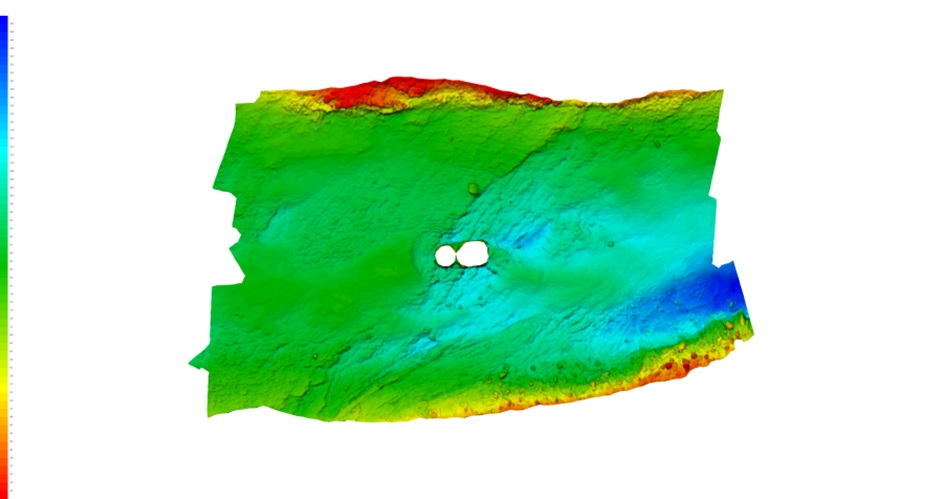

Data Analysis

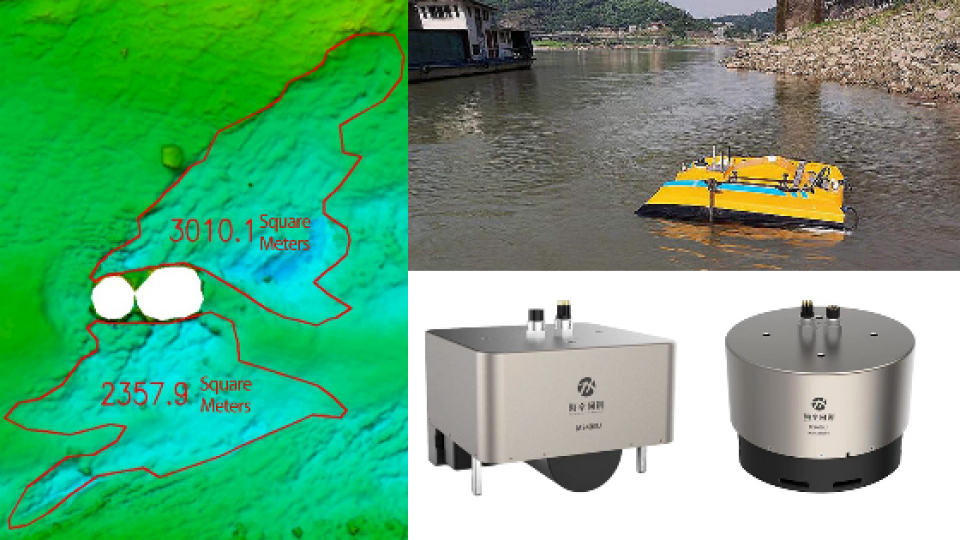

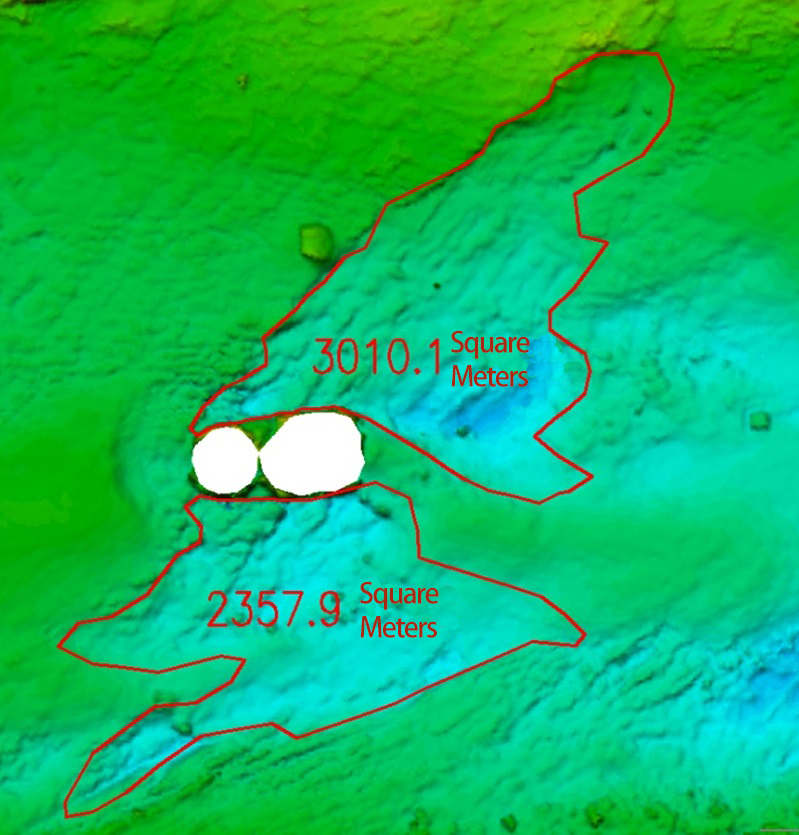

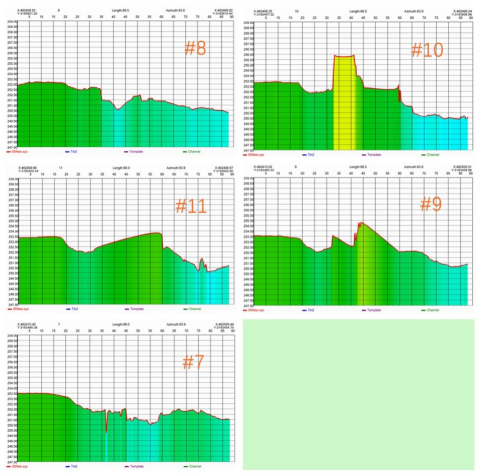

In the TIN model map, the topographic characteristics around the bridge pier are very obvious and the scouring & siltation had been very serious. According to the topographic fluctuations, draw the edge of the scouring area to form a closed curve via professional post-processing software tools, and automatically calculate the scouring area of 3010.1 m2 in the northeast of the bridge and 235.9 m2in the south of the bridge as shown as below.

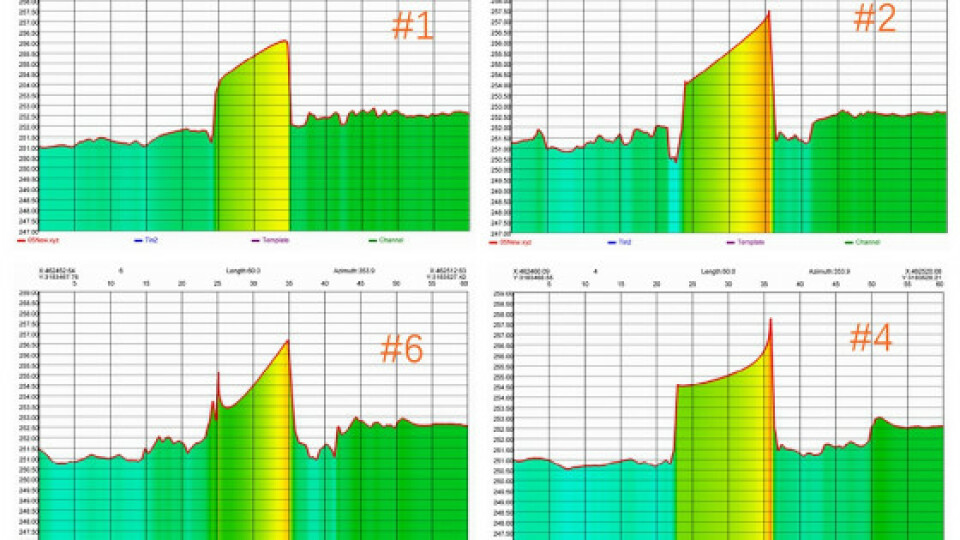

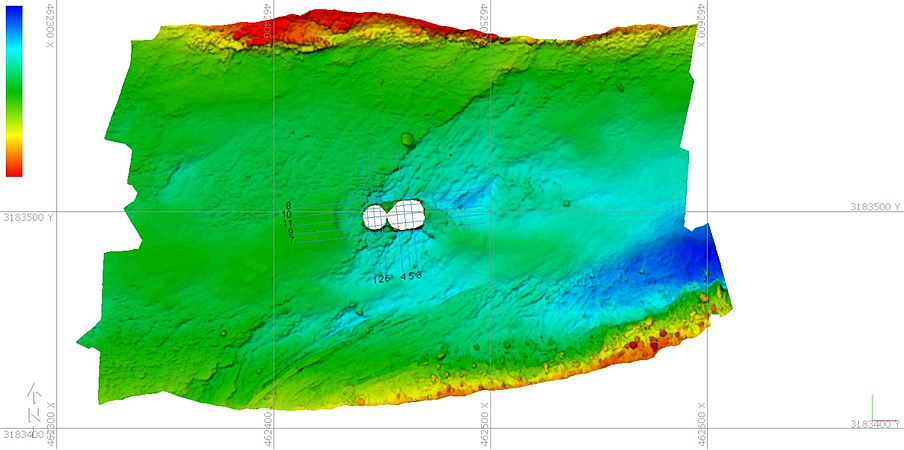

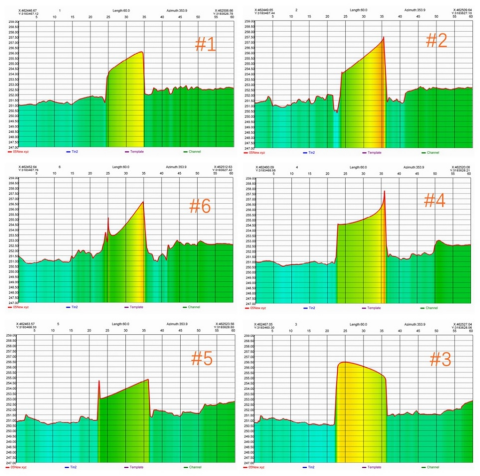

The cross-section of underwater pile foundation scouring is shown in the following figure:

North SouthSection Line No.: 1,2,6,4,5,3;

East-West SectionLine No.: 8,10,11,9,7;

Based on the above data, it can be estimated that the average scouring depth within 15m to the south of the pier is 1.1m, so the total scouring volume is about 259.49m3. And the average scouring depth within 15m to the northeast of the bridge pier is about 0.7m, the total volume is about 2107.07m3. It is consistent with the actual scouring situation and previously estimated data.

Regarding the data accuracy, we used the comparison method to create TIN models for 2 groups of Multibeam sounding data and calculate their difference. The blue colour represents the surveying area, and the red colour is the checking line area. The rendering and range of 2 groups of Multibeam data results are shown in the following picture.

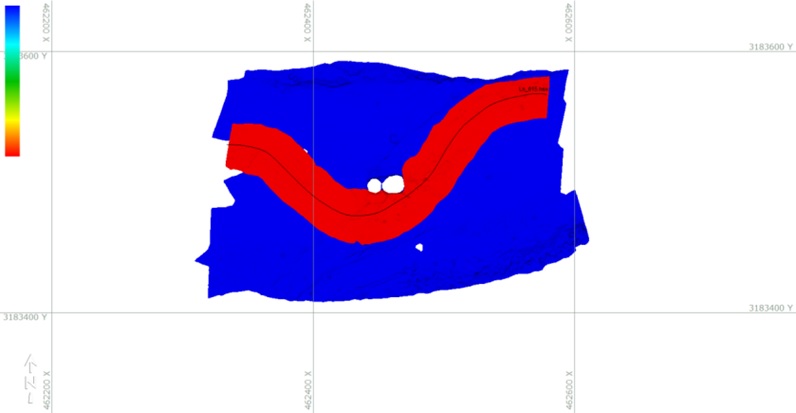

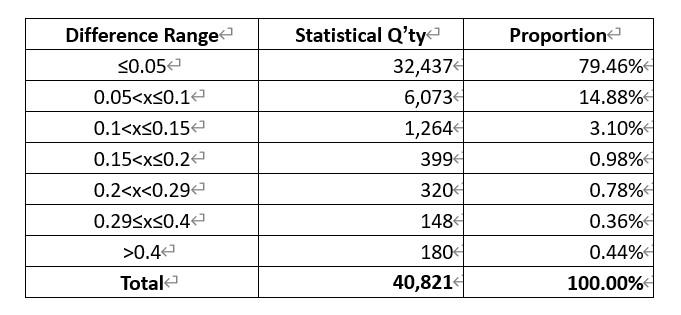

Then calculate the different values and analysis the difference value of the data with the range of 0.5m*0.5m, which is shown in the following figure.

After statistics and comparison, 94.34% of the different values are less than or equal to ± 0.1m. And only 1.59% of the different values are greater than ± 0.20m. Below is the statistical results table.

It can be seen the underwater pile foundation scouring area measured by multibeam echo sounder MS400U is accurate. The data results well reflect the scouring situation of underwater pile foundation. The underwater surveying task is successfully completed.

Conclusion

Through actual application of USV mounted with MS400U, it can greatly enhance the underwater surveying efficiency and safely. At the same time, the data accuracy of MS400U is very high, completely meeting the IHO standard.

Do you have questions about this case study?

Get in touch with Hydro-Tech, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.