Helping Mining Companies Generate Volume Reports Using Laser Scanners

With decades of survey experience under his belt, Barry Hennessy is no stranger to, nor is he resistant to, change. He has seen the industry, the technology that supports it, and his business evolve over time. So when presented with the opportunity to employ new laser scanning technology, it’s not surprising that he embraced it for the opportunities it presented.

That technology, first a Topcon GLS-1000 (next a GLS-1500), is a major part of his Ft. Branch, Indiana-based construction and land surveying business and has, in fact, taken it in directions he never foresaw.

Lets Generate Volume Reports Using Laser Scanners

One of the keys to Hennessy Surveying’s success has been the ability to recognize trending opportunities and broaden its breadth of services. While adding an area of expertise has often been the result of a client request, particularly with the mines, for whom they do a lot of business, there have been times when they recognized the capabilities available with their laser scanner, and created new opportunities.

“Just by nature of its function, laser scanning is ideal for as-builts, ¨said Hennessey. “So we do a fair share of construction-based work providing that service. However, we recently finished a project at the former Indiana Army Ammunition Plant in Charlestown, Indiana that involved moving several large powder storage tanks. The customer wanted to make the re-installation process as smooth as possible. So, using the GLS-1500, we scanned the tanks in place before movement, then brought that scan into Topcon’s ScanMaster software, created a CAD file and provided the customer with all the measurements for the openings, heights and elevations. That allowed them to go ahead and pour concrete in advance, place the necessary mounting bolts, basically have the new site ‘install-ready.¨

He said the size of the tanks, about 40 feet in height, would have made use of traditional surveying techniques nearly, if not altogether, impossible. “And, because the scan essentially gave them a 3D as-built representation, it helped tremendously during the reinstallation process. The GLS-1500 was a perfect fit for this application.”

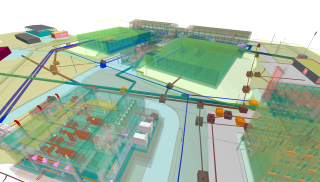

Comparing an older CAD model with a recent scan

Hennessey had the same level of success with his previous instrument, the GLS-1000. One project, which he laser scanned a few years ago, paid dividends then and has returned for an “encore performance.

“This was a huge 180-foot-long corrugated metal, semi-elliptical tunnel for truck traffic,” he said. “We scanned it back in 2010 and now the customer wanted to determine if there’s been any vertical or lateral movement in the structure over the years. I made a CAD model out of the 2010 scan, then took another scan this year and imported it into PolyWorks (InnovMetric Software Inc., Québec, Canada) which works really well with the GLS-1500 and is ideal for doing such comparative analysis. As a result, the customer was able to easily determine if there’d been any deviation between the two; it could not have worked out better.”

"... we can scan that hole, create a CAD file for the mining company and they can calculate what it’s going to take to fill it; it’s fast, safe and accurate."

Owner of Hennessy Surveying, Barry Hennessy

Gathering new opportunities with Laser Scanners

Hennessey says his scanning capability has also allowed him to get directly involved in some post-mining efforts. When pits have reached their end-of-life, mining companies often have to fill and develop that hole. Determining the volume of material needed to do that was, in the past, a long, gruelling effort. For Hennessey and his clients, laser scanning has simplified that task.

“When the mining operation wraps up, these pits often have water and mud in them, not the best environment for a survey effort,” he said. “However, we can scan that hole, create a CAD file for the mining company and they can calculate what it’s going to take to fill it; it’s fast, safe and accurate. The GLS-1500 accurately scans 1,500 feet in any direction, so in just a few minutes we can scan surfaces up to 3,000 meters apart. I actually sat at the bottom of a 40-acre pit one time and scanned the whole thing in about ten minutes. Doing so created a file with about five million points; obviously, that wouldn’t even be considered with traditional GPS.”

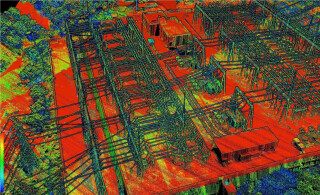

Laser Scanning to gather volumes

Additional mine-related uses include helping mining companies generate volume reports and calculations. “From a safety aspect it can’t be beaten,” he said. “Most mines don’t want surveyors climbing on their stockpiles; with the GLS-1500 we simply set up in two different locations adjacent to the target pile and take our scans.”

From there, he said, the point cloud data from the scanning session is loaded onto an SD card (Hennessey’s preference for data transfer, though the scanner does offer a remote transfer of data to a PC through either USB or wireless LAN), taken back to the office for downloading, then imported into ScanMaster to assign values to the point cloud data. While ScanMaster is designed to actually develop the volume calculations, Hennessey says that most of his mining clients typically want to generate those numbers themselves, he just makes it dramatically faster and easier for them to do so.

“So we take the DWG or DXF file created in ScanMaster, import it into AutoCAD, develop a contour map of that pile, either a grid map or a tin file, for triangulation and turn that over to the customer. We do have a customer, however, for whom we do all the calculations: we tell them how much overburden they’ve removed, how much coal has been moved, how much is still left in the pit, and so on. We do the entire process for them, and we do it all in one day. Over the years we’ve really gotten this down to a science.”

Adding capability with Laser Scanners

Integral to their decision to purchase that first GLS-1000, was a need for the instrument to be versatile. While precision was an obvious need, Hennessey felt that, if the instrument couldn’t serve them in other applications, there was no point in making the investment.

“For us, at the end of the day the GLS-1000 provided the price, the accuracy and the versatility we felt we needed,” he said. “Moving up to the GLS-1500 with its improved range and ability to scan at 30,000 points per second simply made a good instrument that much better. For us, laser scanning is not just a great capability to bring to the table, it’s helped define who we are today.”

Do you have questions about this case study?

Get in touch with Topcon, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

Related products