GNSS Machine Control System Provides Higher Accuracy in Community Construction Project

Faced with a huge site development project and a very tight window of completion, David Brady, Jr. opted for adding larger iron to maximize productivity in the earthwork portion of the job. Brady knew, however, that a larger machine is only as good as the GNSS-based machine control solution that drives it. So when he learned that the new Cat D6N dozer he was taking delivery of could be equipped with 3D-MCMAX, the latest version of machine control from Topcon, he jumped at the chance to be the first in central Florida to boast that system. Today, that daunting development project has been tamed, the work schedule is suddenly a do-able affair and Brady Construction finds itself at the forefront of new GNSS technology.

"Unlike other systems in which the pointer can only indicate the blade’s center and edges, the Topcon solution allows me to place that pointer anywhere on the blade."

Brady’s chief operator Brian Rogers

Machine Control Gets more Work Done

The project that drove Brady to upsize his earthmoving effort was the ongoing expansion of “On Top of the World,” one of the oldest of the many active adult communities proliferating throughout Florida. Developments like these are enjoying a huge upsurge in popularity, according to David Brady, Jr., vice president of Brady Construction of Ocala, Inc.

“The combination of the economy getting better and the fact that Baby Boomers are retiring at record numbers now has been great for developments like On Top of the World,” he said. “Almost every one of these communities in the state, whether it’s this one or The Villages or any of the Del Webb communities, is growing to keep up with the demand, so companies like ours are working hard to help make that growth a reality for them.”

Making the Switch to GNSS Machine Control

The fact that On Top of The World was looking to further expand one of its subdivisions, an area called Avalon, was not challenging for Brady. The developer’s hopes to have work on the new 98-lot community started by mid-July and completed by year’s end, however, was, prompting Brady to consider making an additional capital investment.

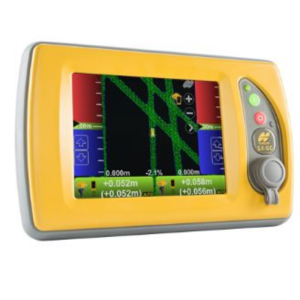

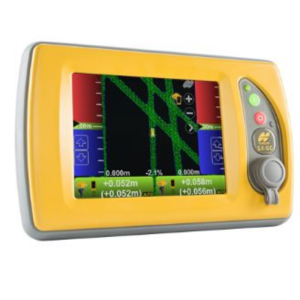

“We knew we wanted a Cat D6N which comes with a 13’ 5” blade, perfect for the size and scope of the work we needed to get done,” said Brady. “And, over the years, we’ve become firm believers in Topcon 3D-MC2 machine control for all of our site work, so we wanted that as well. However, the D6 that shipped was already-equipped with a machine control system of its own. So we contacted Roger Croft at Lengemann of Florida, the regional Topcon dealer, to see what we could do.”

Brady was fortunate in that when he took delivery of the D6N, Topcon had just recently introduced 3D-MCMAX, its newest machine control solution.

“Because I’m always looking for ways to take our operation forward, I had Lengemann install the 3D-MCMAX. It was an excellent decision on our part, the pairing of the new system with the added capacity of the D6N was just what we needed out here.”

"It is perfect for a company of our size, and having the capabilities we do now makes it even better for us to provide the service clients like them expect.”

Vice president of Brady Construction of Ocala, David Brady, Jr.

GNSS Machine Control Delivers

Work at the Avalon site included clearing and grading more than 80,000 cu. yds. of soil for the home sites, grading for roads, and creation of several sizeable retention ponds. Brady said the D6N running the new mastless machine control system impressed them right out of the gate.

“We’ve always been extremely happy with the performance we get out of the machines running 3D-MC2 — we use it on two of our other dozers and a motor grader,” he said. “But we weren’t prepared for what 3D-MCMAX brought to the table. The combination of the D6N’s larger push capacity and the speed and accuracy of the Topcon solution got our attention very quickly. Once my operator was in full swing he was outperforming the other two dozers combined.”

According to Brady’s chief operator Brian Rogers, the new system offers performance advantages far beyond their expectations. “Unlike other systems in which the pointer can only indicate the blade’s centre and edges, the Topcon solution allows me to place that pointer anywhere on the blade,” he said. “This machine has a 13’ wide blade and if I am in a 7’ wide swale, other systems would have a tendency to read the grade beyond the corner of the blade. With MAX, by moving the pointer of the corner of the blade, the system can zero in on the slope of the swale. And all of this can be done right from the screen; there is no having to dig deep into ‘Advanced Settings’ as with other control software.”

Machine Control Offers Stringless Solution

Additional advantages cited by Rogers include the system software’s ability to manipulate line work as needed. He said that should he find himself working an area with a curb indicated onscreen and there is also line work for a storm sewer or other feature conflicting with that curb, he can easily remove the storm’s line work and just follow the curb.

“With other systems, if you bring in a dozen sets of lines, you have no choice but to look at them,” said Rogers. “With this one, I can bring in as many lines as I like, but if I want to turn off half of them and only view the remaining half, I can easily do so. That’s a great feature to have.”

According to Brady, working with On Top of the World has been an ideal relationship. “It is perfect for a company of our size, and having the capabilities we do now makes it even better for us to provide the service to clients as they expect.”

Do you have questions about this case study?

Get in touch with Topcon, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

Related products