Geospatial Solutions Support Rapid Maintenance of Critical German infrastructure

The Alzkanal carries water for hydropower, fire protection and industrial uses in southern Bavaria. The canal was due for periodic inspection, maintenance and repairs. But the channel was filled with deep, fast-flowing water and needed to stay that way as much as possible. Canal operators faced a paradox: How do you develop repair and maintenance plans for something you can’t see or access?

PLANNING FOR THE CHALLENGE

The maintenance was scheduled for a 16.8-km section of the canal. The canal would be shut down during the work of cleaning and repair of cracks or damaged areas. In addition to the expense of materials and labour, local industries would purchase power from other—more costly—sources, and municipalities needed to find alternative sources of fire protection water. The shutdown was planned to last eight weeks, an inflexible schedule due to the shutdown’s high cost and inconvenience.

Canal operators selected SAK Ingenieurgesellschaft GmbH to provide surveying for the canal refurbishment. SAK would document existing conditions and provide data for structural analyses and construction planning. Project requirements included precise measurements of the channel surface at 2cm point density and 3D data extending out 100m along both sides of the canal. SAK planned to use technologies including aerial imaging, photogrammetry, GNSS, total stations and laser scanning.

“Preplanning for construction was very limited because the channel is always full of water,” said SAK’s Christian Fendt.

COORDINATED SOLUTIONS

Two weeks before the shutdown, SAK used Trimble® R10 GNSS receivers and a Trimble S8 1” total station together with Trimble Business Center software to establish more than 150 points to control aerial imaging and ground-based measurements.

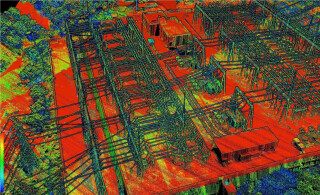

As soon as the canal was drained, SAK commenced work using a Trimble UX5-HP unmanned aircraft system (UAS). They completed eight missions over two days and captured nearly 5,100 images covering the entire length of the project. SAK designed the aerial work to move quickly. At the end of each flight, data was immediately taken by motorcycle to the SAK office while the aircraft was readied for its next flight. Using Trimble UASMaster software, technicians could produce finished ortho projections of the site in roughly seven hours after the raw data arrived. In areas where the canal passed through tunnels, they used a Trimble TX8 laser scanner to collect 3D information. SAK needed only two days to capture comprehensive data for the entire channel.

As construction progressed, SAK scanned each completed segment with the TX8. They complimented the scanning with total station measurements to georeference the scans and capture parts of the channel beneath bridges or still underwater. The UAS, scanning and point data were combined into Trimble RealWorks® software for data management and analysis.

COMPREHENSIVE RESULTS

SAK provided precise models of the channel and repair work. Contractors were paid according to the volume of the material and needed rapid, accurate results. “SAK gained an excellent reputation with the contractors,” Fendt said.

“We were on the construction site daily and in most project meetings. We provided additional surveying services, including volume calculations and layout.”

Following the eight-week shutdown and construction, SAK surveyed the surrounding aboveground elements, such as fences and canal stationing. Finished deliverables included point clouds, digital terrain models, cross sections and georeferenced raw scanning data.

“The project went well and we would use the same approach again. Through good planning and cooperation, small teams can handle huge projects and tight schedules.” Christian Fendt, SAK Ingenieurgesellschaft GmbH

Do you have questions about this case study?

Get in touch with Trimble, Inc., and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.