Ensuring Safeness of a Copper Mine

Copper extraction consists of a series chemical, physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations and other factors. Therefore, the final refining process always remains the same – electrolysis, that often result in toxic waste water. To ensure the safe waste water levels is one of the core challenges in copper extraction industry. The control of acid levels in metal and coal mining industries is a factor of paramount importance. Relevant calculations and precise monitoring can be used to prevent environmental damage and reduce overall exploitation costs. The latest cutting-edge photogrammetric software solution can provide an essential information necessary to monitor the toxic water levels and to create an effective drainage system.

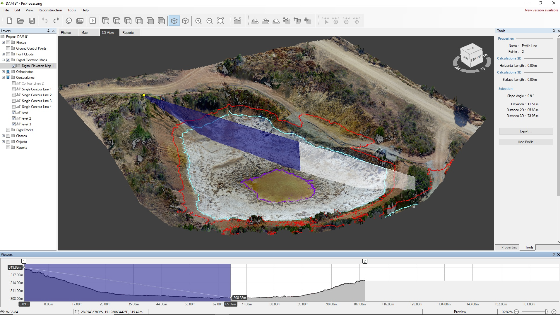

3D Object reconstruction

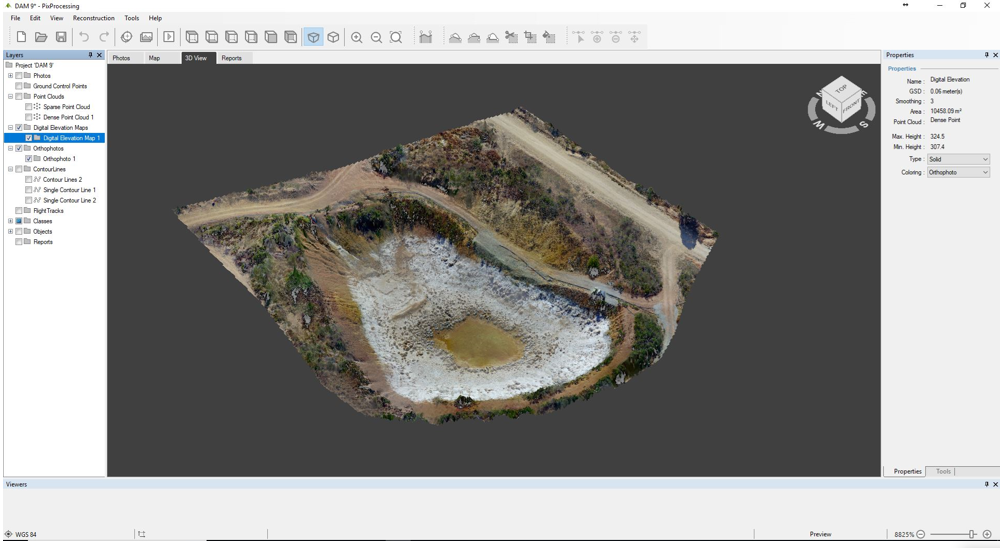

To reconstruct the 3D model of the copper mine with photogrammetric software, we used 236 photos collected with the DJI Mavic Pro drone. Capturing was done with 90 degree camera angle, altitude of 60 meters, single grid overlap 80/80.

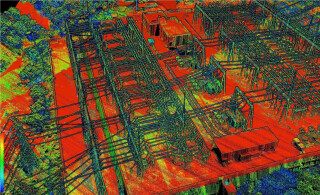

In order to estimate the risk of possible toxic water overflow, firstly we need to accurately determine the elevation map of the zone. Relief can be easily visualized with the generated DEM.

Histogram shading option helps to determine absolute and relative elevation of the area in question.

Setting the critical limits

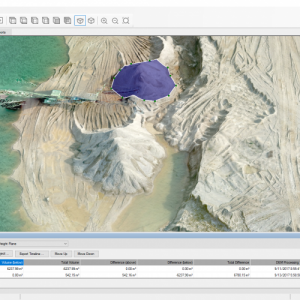

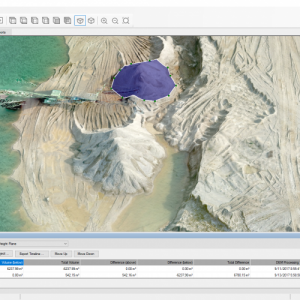

Quick and convenient way to simulate recent, desired or possible water level is the single contour line tool.

Single contour line tool enables you to set the level on the entire object zone by choosing the one single point on the map. Each contour line can be added separately by choosing a different line level.

To calculate the tolerable water level, first of all we have to set:

- The actual water level (the lowest contour line);

- The safe possible water level (the middle contour line);

- The alerting possible water level (the highest contour line).

Given the water volumes of different levels, we can easily calculate the additional allowable water volume.

Disaster prevention

Knowing essential information on the capability to collect the water, it is also necessary to foresee the possible disasters. Simulations of various hypothetical situations can contribute in preparation for potencial misfortunes and catastrophes.

The 1st disaster simulation – excess of the water level

It is possible that the water / precipitation will be more than the available mining pit can accommodate. Then, we need to anticipate the run-off routes for the water and direct it to a safe direction (so that it does not go to the residences or does not pollute the natural environment).

This can be done using the same single contour line tool. When it is placed above the possible rates of water level, the possible drainage gutters begin to be seen, as well as their potential concentrations. So, with the whole Elevation Map, we can deliberately create the water ducts you want to build.

The 2nd disaster simulation – downhill sloping

The 3rd disaster simulation – edge permeability

There are situations, where the causes of a possible disaster may be difficult to see, such as the mining pit overlapping edge. The water can drain through the tiny edges of the duct. In order to evaluate the level of the edges, we will need to profile the terrain using the line tool. If the fluctuations are small, there is nothing to worry about. Alternatively, if the fluctuations are constant and large, there is a risk of leak.

Summary

Every mine is unique due to the extracted / recycled materials, as well as its shape, properties and natural conditions.

Ensuring safety in the mines is one of the most important goals. As a result, timely monitoring, the simulation of various hypothetical situations and the creation of precautionary measures become very relevant.

Using photogrammetric software solutions, important information can be obtained by saving time and investment.

The photogrammetric software helps to accurately assess:

- Current situation;

- Provide future scenarios;

- Evaluate the scale.

Most often, the success of a solution depends not only on accuracy, as well as on timeliness.

Do you have questions about this case study?

Get in touch with Pixpro Ltd, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

Related products