Effluent Lagoon Surveying with the CEE-USV

Scientists and engineers at Environmental Business Specialists (EBS) started a program offering survey-grade effluent lagoon bathymetric mapping to their clients as part of their overall consultancy and support services in the industrial and municipal wastewater treatment industry. Starting with acquisition of the “all in one” CEESCOPE™ echo sounder in 2016, EBS developed in-house field expertise that resulted in a successful program, differentiated from competition offerings often based around non-survey grade recreational depth finders or laborious and costly manual sludge surveys. Three years later, a CEE-USV™ unmanned survey drone was added to the program. EBS can now offer surveys with attractive safety and cost benefits to the treatment facility operator, while retaining professional grade data for their clients. Using HYPACK software throughout the hydrographic program, EBS survey crews can switch from manned to unmanned surveying with no changes in the data acquisition process.

Scientists and engineers at Environmental Business Specialists (EBS) started a program offering survey-grade effluent lagoon bathymetric mapping to their clients as part of their overall consultancy and support services in the industrial and municipal wastewater treatment industry. Starting with acquisition of the “all in one” CEESCOPE™ echo sounder in 2016, EBS developed in-house field expertise that resulted in a successful program, differentiated from competition offerings often based around non-survey grade recreational depth finders or laborious and costly manual sludge surveys. Three years later, a CEE-USV™ unmanned survey drone was added to the program. EBS can now offer surveys with attractive safety and cost benefits to the treatment facility operator, while retaining professional grade data for their clients. Using HYPACK software throughout the hydrographic program, EBS survey crews can switch from manned to unmanned surveying with no changes in the data acquisition process.

Environmental Business Specialists (EBS), Mandeville, Louisiana USA are an independent wastewater treatment consulting and training company that provides solutions for operational and training challenges in the wastewater industry. EBS scientists are advisors for clients, helping them protect rivers, lakes, streams, and estuaries while supporting their financial goals and long-term sustainability. EBS provides specialized on-site support to industrial wastewater treatment systems, including on-going monitoring and sampling.

In 2016, EBS decided to develop a professional-grade hydrographic survey capability to help clients understand sludge accumulation in their lagoons. After field-testing several echo sounders, EBS selected the dual frequency CEE HydroSystems CEESCOPE™ owing to its industry-leading ease of use. With a GNSS receiver and echo sounder contained in a single portable unit, the CEESCOPE offers a simplified operation without compromise in data quality. Continuing EBS’ commitment to obtain the highest quality, credible, and trustworthy data for clients, industry-leading HYPACK acquisition software was selected.

On the value of their hydrographic survey data to clients, Heather Edmunds, EBS Staff Scientist explains: “In industrial wastewater treatment systems, knowing the current water volume available for treatment is crucial as it directly relates to the time available for treatment. From the first day industrial systems are put into operation, basins are decreasing in volume. Routine hydrographic surveys show changes in volume that can be tracked, and results used to inform capital spending projects such as dredging. These surveys not only inform when dredging might be needed but where in the basin dredging is needed most.”

CEESCOPE™ “all in one” GNSS and echo sounder.

With the CEESCOPE installed on a manned boat “over the side” pole mount, EBS were able to quickly commence their new surveying services, initially assisted by field training from CEE staff.

CEESCOPE™ manned boat survey - HYPACK software.

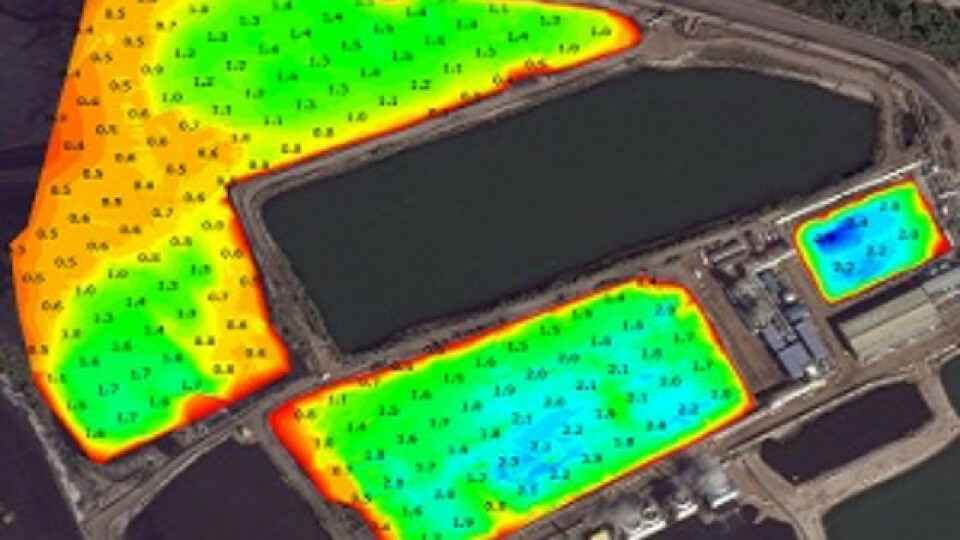

HYPACK MAX Software TIN model color surface.

Owing to the success of EBS’ program, demand for surveys increased and while looking for ways to promote safety as a priority, EBS reviewed adding an unmanned survey boat to their hardware inventory. After a test of the CEE HydroSystems CEE-USV™, EBS acquired the system in 2019, including the telemetry-enabled CEESCOPE-LITE™ dual frequency echosounder. By using the remotely-operated boat to conduct a survey, EBS can now provide surveys across water bodies not traditionally considered accessible. The shore operator is able to see real-time HYPACK survey data on the field PC and can precisely navigate the boat along pre-planned survey lines to ensure consistent and adequate coverage. Being a fraction of a standard boat size, the USV can easily be placed into elevated or lowered structures, eliminating the safety concern of having a person in either of these situations. Additionally, water bodies considered hazardous or not designed for personnel entry may be safely surveyed. Some examples are liquor ponds, surge and/or stormwater ponds, municipal lagoons, and/or hazardous waste ponds. The survey crew can be reduced from three to two, while still maintaining safety on site.

The CEE-USV™ Surveying at 4.5mph.

The first survey after putting the USV into service was conducted with the manned boat CEESCOPE and the CEE-USV used simultaneously to validate results. As the CEESCOPE echo sounders are common to both boats, not only are data consistent but the software drivers and setup are identical. This means users can use the USV with little or no additional knowledge required, and also switch between the two methods easily. EBS quickly discovered that owing to the better manouvering characteristics of the USV compared to a manned boat, especially in small lagoons, better data coverage is typically attained, resulting in more consistency in identifying features in sludge deposition.

Comparing CEESCOPE™ manned boat (left) and CEE-USV™ (right) track lines in a small lagoon.

Already, the USV has been used in several varied scenarios. For example, a large 230 acre pond was surveyed where a manned boat could have been a good approach, but the clients preference was not to have people on the water. At the other end of the size spectrum, the USV was used in a 0.7 acre pond completely surrounded by a fence limiting traditional boat access to the pond, with the pond too small to maneuver a traditional boat.

Lagoon system survey results from the CEE-USV™.

At a chemical refinery with multiple ponds, with the largest only 3 acres, launching a traditional boat was simply not a viable proposition owing to the enormous time needed for recovery and relaunch in all the ponds. With the CEE-USV, EBS were able to greatly reduce the survey project cost for their client by minimizing mobilization time moving from one pond to the next.

The CEE-USV™ on a large wastewater lagoon.

The USV was also deployed at a paper mill with 50+ diffused air laterals, one every 30ft, presenting a considerable challenge. The client’s preference was to not have people on the water but also navigating a traditional boat between the laterals would have been difficult. This situation presented an ideal project for a USV. While the CEE-USV used by EBS does have the capability to be used with the the CEE-PILOT™ robotic autopilot navigation system, the wastewater lagoon environment presents a significant challenge for a waypoint-based navigation system. With obstructions and unknown obstacles in the lagoons, programming the autopilot route beforehand would often be sending the boat across cables and into equipment. Operating with manual navigation is the common sense approach for these types of surveys, especially as most are relatively small areas. As both the CEESCOPE and CEE-USV are designed with the goal of reducing complexity of field equipment to an absolute minimum, both systems are well suited and proven for challenging industrial environments such as those facing EBS.