Dredging Precision Using an EdgeTech Sub-bottom Profiler

IHC Systems B.V. is the market leader in process monitoring, control, automation, simulation and the integration of dredging, nautical and hydrographical tasks on board of dredgers. The company is always on the forefront of utilizing new technology to enhance the solutions they provide to the dredging community. IHC Systems B.V. is well versed in the use of leading edge electronics, information technology systems and sensors that aid them in their business of providing highly advanced technology based solutions.

Scenario

Mineral dredging and mining underwater can be a particular challenge because concentrations of deposits are often covered by, or near, other layers of material. Economically valuable deposits such as gold, tin, pewter, ilmenite, rutile or zircon are often buried under layers of sand, mud and clay. Pewter in particular, is challenging because it is often located under the sea fl oor, in valleys and most often on a rocky bottom. The challenge for a mineral dredger such as PT Timah is to fi nd the most economical way to extract and separate the “good” material from the “bad’. In this case, to fi nd and extract the pewter layers while avoiding the hard rock areas. Traditionally dredge operators use core samples and charts to estimate the location of the valuable layers of material. They then position their extraction tools to get close to the valuable layer while maintaining a large safety margin. This method while acceptable, is often more costly than being able to more precisely extract the valuable material with minimal core samples. One of the technologically advanced means to assist in this process is the utilization of an acoustic sub-bottom profi ling system.

Solution

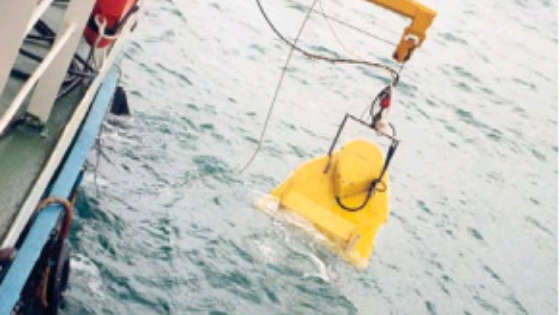

IHC provided an advanced technology based solution to PT Timah which aided them in their dredging operations. A critical part of this system was the EdgeTech SB-512 subbottom profiler. The EdgeTech system was mounted on a research vessel and sub-bottom profile data was collected. This profi le layer information was then converted to Digital Terrain Models (DTM). The DTMs were then transferred to the mining vessel where they used IHC Systems’ Dredge Track Presentation System (DTPS) for online visualization of the mining operation.

The SB-512 sub-bottom profi ler is one system from a full line of acoustic sub-bottom profi lers, side scan sonars and bathymetry systems produced by EdgeTech. The versatile wideband Frequency Modulated (FM) sub-bottom profi ler generates cross-sectional images of the seabed and collects digital normal incidence refl ection data over many frequency ranges. The system utilizes EdgeTech’s Full Spectrum® Chirp technology which provides high resolution imagery of the sub-bottom materials and layers at penetration depths down to 100 meters below the sea fl oor, quarry or river bottom surface. EdgeTech’s Full Spectrum® Technology has several distinct advantages over other sonar systems, including increased penetration and higher resolution.

Using the SB-512 sub-bottom profi ler IHC Systems could effectively “take an x-ray” of the sub-layers underwater and below the area of interest for the dredger. The SB-512 operates at 5-12 kHz and provides a great balance between picture resolution and area penetration. The image captured by the SB-512 is displayed and stored on standard computer running EdgeTech’s JStar software. The sub-bottom profi ler uses the differences in acoustic attenuation of the various layers to display an accurate measurement of how deep each layer is in the area of interest.

The use of the SB-512 sub-bottom profi ler and subsequent data provided by the IHC Systems’ DTPS for online visualization of the mining operation, allowed PT Timah operators to position their extraction equipment close to the valuable pewter material layer while remaining clear of the rocky subsea terrain. Positioning the cutter and extraction tools closer the valuable materials meant less processing time and individual core samples throughout the area of interest for the dredger and therefore a cost savings for the operation.

As an additional note, EdgeTech has recently released the 4600, a new product that provides side scan sonar and bathymetry images co-registered. This three dimensional view of the seafl oor could offer tremendous benefi ts to the dredging community as well. Pre and post site survey work can be completed in real time with the 4600. With the advancements in technology, detailed views underwater of the bottom and sub-bottom are now available in easy to use commercial off the shelf systems.

Do you have questions about this case study?

Get in touch with Edgetech, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

![3月21日-封面[1].jpg](https://cdn.geo-matching.com/voeE1ywo.jpg?w=320&s=6b3b1a0215d770f8797653e9202a8f52)