Dozers Using Machine Control Systems Benefit From an Efficient and Accurate Workflow

When On-Track Construction (OTC), a company with no experience using GNSS solutions, landed a major project at the Buffalo International Airport, followed by other sizeable site work contracts, they knew their time to embrace that technology had come. After purchasing a GNSS base/rover and a dozer equipped with Topcon 3D-MCMAX, the latest generation of machine control, they immediately saw production soar. Today, less than a year after that initial investment, the company is able to tackle more work than at any point in their relatively short history and is already eyeing a second identical system.

Machine Control Systems are a Justified Solution

Once focused on building moto-cross tracks for customers around the country, company president, Jesse Milley, and his brother Matt switched gears after the economic downturn. In 2010, equipped with just a mini-excavator and a skid-steer loader, they began bidding and landing small commercial jobs that included site work, (excavating and grading) as well as utility installation (storm, sanitary, water).

“By 2013 we had built the business up to where we were doing about $650,000 of work annually,” he said. “I’d already been talking with Admar Supply for a couple of years and knew that GPS and machine control were things we needed to look into. But, up until that point, we didn’t really have enough large-scale jobs to justify the expense; for a smaller contractor, that’s a huge investment.”

Landing a couple of huge projects in a row, however, helped Milley start looking at GPS, and demo sessions with Admar, showing what Topcon 3D-MC2 could do won them over. Understandably cautious, they first committed to renting a dozer equipped with the solution.

Dozing Large Areas Made Easy

As it is for most smaller contractors, OTC’s site work was, at one time, a staking-intensive effort. Milley said that changed immediately upon bringing GNSS into the picture.

“We did a 12-acre site, which included stripping, importing 10,000 yards of soil, and laying down a sub-base, in 25 days,” he said. “Pounding down lath as we’d done for years, would easily have taken us twice that time.”

After only one week using the Topcon 3D-MC2 solution, Milley was on the phone with Admar confirming that this was, indeed, the direction they wanted to take. They were surprised to learn that there was an even newer system about to be introduced.

"The performance of 3D-MCMAX is impressive overall, but even more so on slope grading , the blade just nails the contours perfectly and doesn’t skip around at all."

Jesse Miley

Fast and Steady, in Full Control

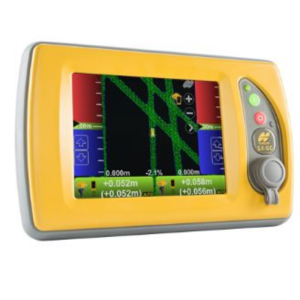

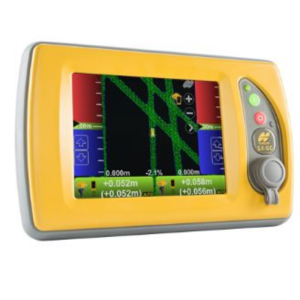

The system to which Milley was about to commit, Topcon 3D-MCMAX, uses a pair of Inertial Measurement Units (IMU) that enable an operator to blade faster and smarter and do so without the need for a mast on the machine. Having two IMUs working together quickens the response time, allowing for both tighter turns and smoother grades.

“The newer system was well within our budget, so we ordered it for the Komatsu D39 PX dozer we were buying,” said Milley. “I wanted to make sure we had the system that was the most productive as we moved forward and we definitely got that. The performance of 3D-MCMAX is impressive overall, but even more so on slope grading, the blade just nails the contours perfectly and doesn’t skip around at all. While you generally don’t want to run a dozer in third gear, on a building pad or similar scenario you probably could with this system, it’s that responsive.”

Because the machine is mastless, Milley said worker safety is yet another benefit. “We work throughout western New York, an area is obviously known for its snow and ice. No longer needing to climb up to install antennas every morning then again to take them down every night is an excellent safety plus. At the end of the day, we simply take the screen out of the cab, lock the machine and go home.”

Machine Control Systems Allow Easy Integration

Other purchases OTC made include a Topcon HiPer V base/rover and a pair of field controllers (FC-500 and FC-5000). In a matter of months, the company went from no GNSS capability to a complete geopositioning solution. And they recently brought it all to bear doing site work for an addition to the back of an industrial manufacturer’s building, as well as a sizeable, detail-laden retention pond and access road.

“The 26,000 square foot addition extended right into a huge bank, so we first had a 7,500-yard cut to handle,” he said. “The design included lots of contour lines and swales and the MAX system just cut them right in and moved on to the next section. Similarly, work on the pond called for the removal of about 2,400 cu. yds. of soil and creation of some interesting contours the engineers designed in. It would have been a nightmare to do using stakes, but was a breeze with the Topcon solution.”

Milley said OTC’s workload has continued to pick up to a point where they are looking at about $4.4 million in business this year. To address that growth, they are up to ten field personnel and generally have two crews going at a time. “It’s important to note that, without the quality operators and labourers who have joined the OTC team over the years, none of our success would have been possible,” said Milley. “They are truly a dedicated, gifted group of individuals and I couldn’t be prouder of the work we’ve done together.”

Quick, Efficient and Accurate

The issue of how quickly, efficiently and accurately 3D-MCMAX can get things done has also forced Milley to rethink his overall business model for OTC. Projects that once seemed to be an impossibility, are now definitely in their wheelhouse; project schedules that once seemed impossibly tight are now do-able, opening the door to additional work.

“I have to rethink the whole process because of how fast the workflow on site is right now,” he said. “Adding 3D-MCMAX has changed that part of the job immensely. We started this business with the intention of running with the big boys; the new technology has helped make that happen and I’m sure it’s only going to get better.”

Do you have questions about this case study?

Get in touch with Topcon, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

Related products