CSX Rails Against Traditional Asset Management

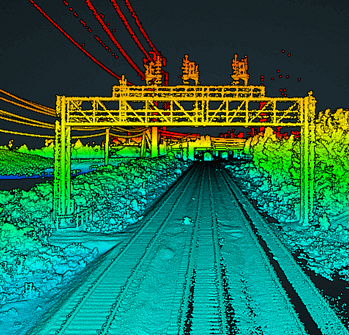

The CSX team found utilizing the Phoenix LiDAR Systems SCOUT systems allowed them to survey an entire railroad at an unprecedented level of accuracy and maintain those assets in an industry data model.

Challenge

CSX is one of the nation’s leading transportation suppliers of rail-based freight and intermodal containers, operating and managing over 21,000 miles of track spanning 23 states, DC, Ontario and Quebec. Nearly two-thirds of Americans live within CSX’s service territory.

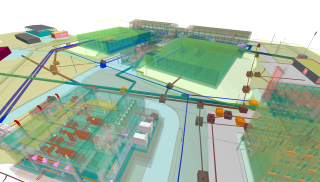

In 2008, the Rail Safety Improvement Act mandated the implementation of Positive Train Control (PTC) systems - technologies designed to automatically stop a train before certain accidents related to human error can occur. PTC mandated CSX to survey the entire railroad at an unprecedented level of accuracy and maintain those assets in an industry data model. The project required maintenance of all changes - quickly becoming a daunting task of change management throughout their operation network with the added challenge of railroaders’ hesitancy to do anything that interrupts the flow of train traffic.

Solution

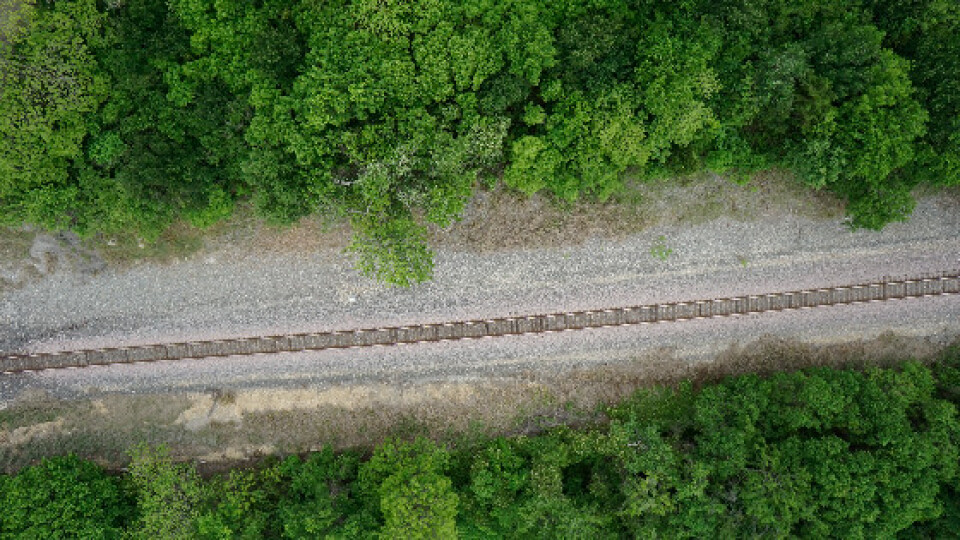

Previously, CSX sent teams out with GNSS survey equipment to walk the track, taking shots every 50 feet to update their asset inventory and change inventory for validation. Fast forward to today, CSX utilizes the Phoenix Lidar SCOUT systems to deploy their high-rail trucks and geometry cars to continuously collect data for 200+ mile corridors - a massive saving in time and, more importantly, a vast improvement in safety.

Parameters

Site: Rail Corridor

Solution: SCOUT-16 & SCOUT-32

AGL: 4m

Ground Speed: 25-40mph

Point Density: 800+ ppsm

Application

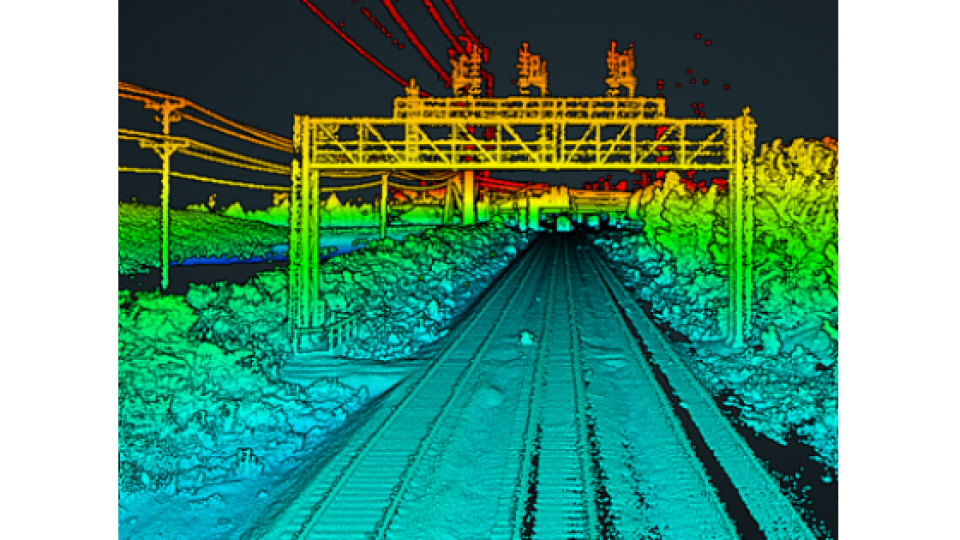

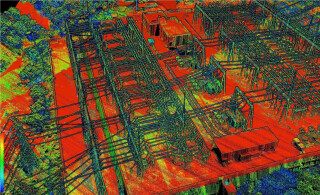

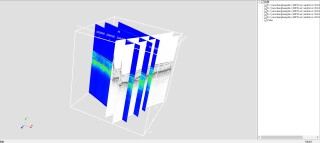

The transportation side of CSX moves multi-million dollar equipment, from large generators to military equipment. To ensure the expensive cargo arrives safely at its destination, CSX first scans the planned route to extract cross-sections of bridges, tunnels, and other overhead obstructions from the Lidar to identify clearance hazards before transport.

Results

CSX now owns and operates seven Phoenix Lidar systems. (4) SCOUT-16 systems mounted on high-rail trucks with Ladybug cameras and (3) SCOUT-32 systems permanently installed on the backs of rolling rail cars. With this flexibility, the high-rail trucks can travel on both road and railroad, enabling them to go anywhere at any time to support immediate business requests. The rail-based geometry cars are designated to travel and cover the 21,000+ mile network at least once per year as part of their safety protection protocol, with Lidar continuously collecting data.

Do you have questions about this case study?

Get in touch with Phoenix LiDAR Systems, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.