CHCNAV GNSS Solutions Improve Mining Productivity on Sumatra, Indonesia

The latest GNSS technologies from CHCNAV have been used recently in combination with vocational training on the island of Sumatra to improve the productivity of surveying activities and hence contributed to local economic development.

The island of Sumatra is one of the largest islands in Indonesia, Java, and south of the Malay Peninsula. It is known for its fertile soils, its wide variety of animals, and its natural resources, including coal, crude oil, and natural gas. These support some of Sumatra’s key economic activities, generating more than 60% of the region’s income. In addition, the government of Sumatra also places great emphasis on vocational training as local human resources play an important role in contributing to economic development on the island.

Figure 1. The island of Sumatra on the map

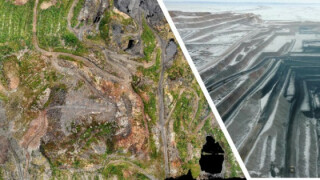

Mining and quarrying are demanding industries for the topographical surveys In Sumatra. PT Bukit Asam (coal), PT Semen Baturaja (cement), and PT Pupuk Sriwijaya (chemicals) are among the largest companies there. They are continuously investigating new technologies to improve their workflows, methodologies and overall organization. With the use of increasingly efficient equipment and techniques for full 3D digitization of sites, the operation of a mine or an open pit has been greatly optimized; at every stage, from exploration to operation of mines or quarries, CHCNAV solutions were used and recognized for their accuracy and affordability by all stakeholders

USERS PAIN POINTS

When customers implementing new methodologies for 3D mapping and surveying frequently, they experience difficulties. These can be summarized as follows:

- The existing metrology tools may be technologically outdated, e.g., a simple theodolite and level for topographic surveys.

- High and recurring maintenance costs of aging equipment consume part of the financial resources at the expense of acquiring new equipment.

- Large mining companies have difficulty recruiting high-quality employees as they prefer to use up-to-date equipment such as GNSS receivers, photogrammetric drones and Lidar.

- Veteran employees are reluctant to learn how to use new equipment and different software, such as switching from theodolites to GNSS technology.

- High-tech solutions are often associated with high-cost equipment and are therefore considered out of reach from a financial point of view.

SOLUTIONS IMPLEMENTED

1. The availability of technologies that meet the specific needs in mines and quarries, such as harsh operational conditions and remote sites.

The IP (water and dust protection) certification level and the ruggedness of the i73 and i90 GNSS receivers provided maximum confidence in their daily use and drastically reduced hardware downtime. In addition, the GNSS technology, such as iStar (the newest GNSS PVT (Position, Velocity, Time) algorithm for CHC Navigation's GNSS RTK receivers that allows tracking and usage of all the 5 main satellite constellations (GPS, GLONASS, Galileo, BDS or BeiDou system, QZSS) and their 16 frequencies with optimal performance) optimized the performance of GNSS surveying, both in terms of positioning accuracy and its availability in challenging environments.

Figure 2. Setting up control point for base-rover GNSS RTK

2. The adoption of GNSS technologies for first-time users by simplifying work processes.

The integration of GNSS+IMU modules allowed surveyors to survey points without the need to level the range pole. Software development also played a significant role in this process, enabling the implementation of automated processes: safety checklists for the use of drones, codification of topographic surveys for optimal data processing using CAD software, etc.

Figure 3. Staking out with i73 GNSS rover

3. Lastly, systematically conducting training sessions with field operators contributes to increased productivity and a rapid return on investment.

The training program for this project covered the fundamentals of GNSS RTK systems. Although most of the sites in this project have network coverage for operation in NTRIP RTK mode, the ability to use the integrated radio modems provided a valuable operational backup. The data acquisition phase with an extended codification (addition of photos, video and voice messaging to the survey points coordinates) facilitated the final processing step, cartographic rendering, volume calculation, etc.

Figure 4. GNSS training by CHCNAV expert

GNSS PRODUCTS USED

The i73 GNSS Receiver is more than 40% lighter than a typical GNSS receiver, making it more convenient to carry, use and operate without fatigue. The i73 compensates for up to 45° tilt of the survey range pole, eliminating the challenges associated with surveying points that are concealed or unsafe to reach. Its integrated high-capacity battery provides up to 15 hours of operation in the field. Full-day projects can be easily completed without worrying about a power outage.

The i90 GNSS Receiver with embedded 624-channel GNSS technology takes benefit from all GPS, GLONASS, Galileo and BeiDou signals and provides robust RTK position availability and reliability. The 4G modem brings ease of use when working within RTK networks. The internal UHF radio modem allows long-distance base-to-rover surveying over distances of up to 5km.

LandStar7 Software is the latest field-proven survey software solution for any Android device and CHCNAV data controllers. Designed for high-precision surveying and mapping tasks, LandStar7 provides seamless workflow management from field to office and an easy-to-learn and easy-to-use graphical user interface to complete projects efficiently.

Figure 5. CHCNAV i90 GNSS, i73 GNSS and LandStar7 App

CONCLUSION

- The project in Sumatra was realized in accordance with the customer’s requirements. Whether capturing natural surfaces in the exploration phase or conducting control surveys, calculating available resources, managing road ramps or calculating bench heights and widths during the mine exploitation phase, using CHCNAV geospatial solutions has been increasing the safety and productivity of quarries and mines in Sumatra.

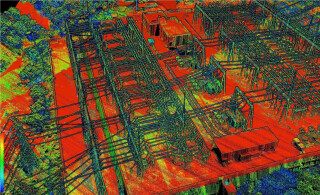

- The availability of CHCNAV experts in mapping, surveying, Lidar and photogrammetric drone survey applications contributed to the user adoption of the new 3D digitizing methodology.

GNSS RTK receivers, local or regional GNSS RTK networks, airborne unmanned aerial vehicles (UAVs or ‘drones’), photogrammetry, and the latest Lidar technology are all solutions CHCNAV provides to help mine and engineering companies increase their productivity. The affordability of CHCNAV’s cutting-edge products contributes to the extremely rapid return on investment and significantly removes financial barriers.

Do you have questions about this case study?

Get in touch with CHC Navigation | CHCNAV, and they would be happy to answer any questions you have about pricing, suitability, availability, specs, etc.

Related articles